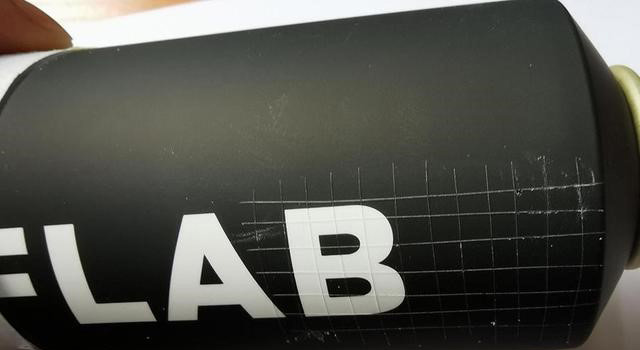

Yes, sure. KingStar drinkware customized with your logo and brand colors are great gifts for office employees, students, event attendees and clients, and make your business top-of-mind. They are an impressive addition to gift baskets.

Click and read more about KingStar corporate gift program