Nowadays, the competition in the vacuum flask manufacturing industry is becoming increasingly fierce, and consumers are demanding higher and higher product quality. Under this circumstance, product quality management and control are particularly important to whether a company can occupy a place in the fierce market. The quality level of the products is closely related to the quality management scheme. KingStar, the top OEM water bottle manufacturer, attaches great importance to product quality management and Improve the quality management system.

KingStar has implemented total quality management for more than ten years. The content of total quality management includes product quality management, service quality management, and internal workflow management.

Click here to read more about Vacuum Insulated Stainless Steel Water Bottle Tumbler Manufacturing Process

In order to produce high-quality vacuum insulated stainless steel water bottle tumblers, KingStar focus on 6 aspects:

- Human factor: The theoretical level of the engineer, the operation ability of the technician and the proficiency of the operator.

- Machine factor: The mechanical automation level of the production workshop;

- Material factor: Incoming quality inspection of insulation flask materials;

- Factors of process and operating procedures factor: Optimization and improvement of the production process of vacuum insulated flask

- Environmental factor: Production environment

- Factor of measurement: mainly refers to whether the method adopted in the measurement is standard and correct.

vacuum flask manufacturing

Build a Professional Drinkware Quality Management Department

The most important factors affecting product quality are the theoretical level of the engineer, the ability of the technician to operate, and the proficiency of the operator.

1) For the admission of technical personnel in the water bottle manufacturing workshop, the director of the production department shall strictly control the admission of technical personnel in the workshop, and the admission of technical personnel in the workshop shall be assessed twice. The purpose of the first assessment is to select the personnel who are qualified to participate in the training courses of enterprise workshop technicians. The selected personnel will receive a month-long workshop technical-level training, and the training work is in the charge of the team leader and supervisor of each workshop. After one month’s training, the team leader and supervisor of each workshop will select the personnel who can become regular employees of the enterprise through some skills assessment.

2) Strengthen a quality inspection team

Overview of the quality inspection team

In the report of establishing the quality inspection team, the information of each quality inspector is written in, which can not only enhance the sense of responsibility of each quality inspector, but also attract other employees to participate in each quality inspection activity, and enhance the quality awareness of each staff member in the enterprise.

Responsibilities of the water bottle manufacturing quality inspection team

(1) Be responsible for the quality inspection of work in process and finished products in each link of the production process.

(2) Be responsible for inspecting the quality of raw materials and products to be put into storage.

(3) For each link that may have an adverse effect on product quality, we should strictly check one by one.

In addition, any major adverse effects caused by the inspector’s lax quality inspection shall be borne by the consequences.

Specific work contents of quality inspection team members:

(1) Provide services for the production workshop, provide product quality information, timely and quickly feedback all kinds of information to the production line at all levels, so that all departments can quickly control the product quality according to the feedback information;

(2) Supervise and inspect the product quality management of the workshop, and urge the benign operation of various quality management work;

(3) Certification of product quality of each department plays a role of strict quality control.

(4) The quality inspection team should check the running state of the machine every day to ensure that each machine can efficiently complete the production work of the vacuum insulated flask.

(5) According to the pass rate of each link in the workshop, the operator of each link is scored, and then the reward and punishment mechanism is carried out.

Click here to read more about Vacuum Insulated Stainless Steel Water Bottle Industry Standard and Testing Methods

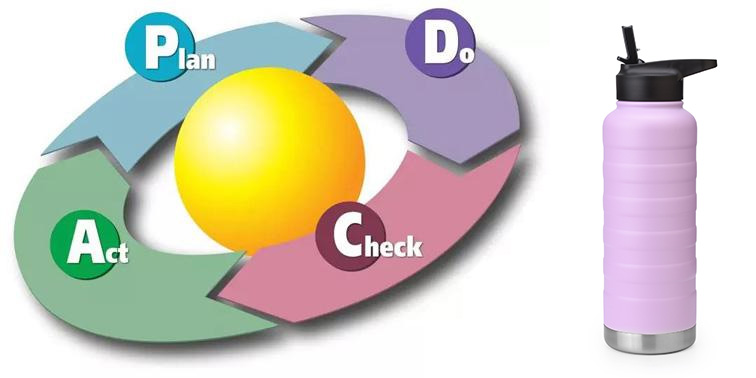

At KingStar, PDCA method has been used to improve the vacuum insulated stainless steel drink bottle quality:

P (Plan): according to the actual situation, the top leaders of the company put forward the goal of the qualified rate of the finished product of insulation flasks (for example, the qualified rate of the first finished product must reach ≥ 98%). According to the quality qualified rate goal, the technical director formulates the visual quality inspection plan.

D (Do) implementation: other members of the quality inspection team implement the measures proposed by the scheme.

C (Check) inspection: evaluate the results after the implementation of the quality inspection plan, and find out the problems that produce the results.

A (Action) processing: the results of the examination are processed, the successful experience is affirmed and standardized; We should also sum up the lessons of failure and pay attention to them. The unsolved problems should be submitted to the next PDCA cycle for a solution.