How to ensure that stainless steel drinkware does not rust? This is a question our customers often ask us. As a reliable stainless steel drinkware manufacturer, KingStar explains our test in detail in this post – Salt Spray Test for Stainless Steel Drinkware.

The Importance of Salt Spray Testing for Stainless Steel Water Bottles

Stainless steel is a widely used material in the drinkware industry, valued for its corrosion resistance and oxidation resistance, allowing it to maintain stable performance in many environments. However, the corrosion resistance of stainless steel is not absolute and can be influenced by environmental factors. To assess the corrosion resistance of stainless steel water bottles in various environments, KingStar conducts salt spray tests on each batch of bottles.

The salt spray test for stainless steel water bottles is a method of simulating the corrosive effects of salt spray in natural environments on materials. Through this test, the corrosion level of stainless steel water bottles in specific environments can be evaluated, thereby assessing their corrosion resistance. The standards for stainless steel salt spray testing are mainly determined based on the testing method, testing conditions, and testing results.

Methods of Salt Spray Testing for Stainless Steel Water Bottles

Salt spray tests for stainless steel include neutral salt spray tests, acetic acid salt spray tests, copper salt accelerated acetic acid salt spray tests, and alternating salt spray tests.

(1) The neutral salt spray test (NSS test) is the most widely used accelerated corrosion test method for stainless steel drinkware testing. It uses a 5% sodium chloride saline solution with a pH value adjusted to the neutral range of 6.0-7.0 as the spray solution. The test temperature is set at 35°C, and the salt fog settling rate is required to be between 1~2ml/80 cm 2.h.

(2) The acetic acid salt spray test (ASS test) is developed based on the neutral salt spray test. It involves adding some glacial acetic acid to a 5% sodium chloride solution to lower the pH value of the solution to around 3, making the solution acidic and transforming the resulting salt spray from neutral to acidic. Its corrosion rate is about 3 times faster than the NSS test.

(3) The copper salt accelerated acetic acid salt spray test (CASS test) is a recently developed rapid salt spray corrosion test. The test temperature is set at 50°C, and a small amount of copper salt—copper chloride is added to the salt solution to induce corrosion. Its corrosion rate is approximately 8 times that of the NSS test.

(4) Alternating salt spray test is a comprehensive salt spray test, which combines neutral salt spray test with constant humidity test. It is mainly used for cavity-type whole machine products, where salt spray corrosion occurs not only on the surface of stainless steel water bottles but also inside the products through the permeation of humid conditions. It alternates the products between salt spray and humid heat environments. Click and read more: Stainless Steel Water Bottle Reliability Test: Fatigue Test of the Lid

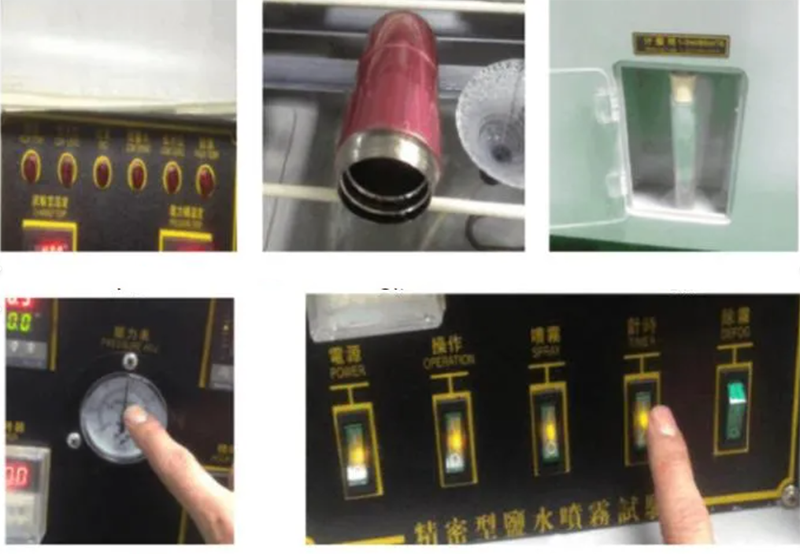

Equipment for Salt Spray Testing of Stainless Steel Drink Bottles

The equipment commonly used for salt spray testing of stainless steel water bottles is salt spray test chambers, which work by generating a salt spray environment to simulate marine climate conditions for testing the corrosion resistance of stainless steel products.

Testing Conditions for Salt Spray Testing of Metal Jugs Tumblers

The testing conditions for salt spray testing of stainless steel water bottles are also crucial. Generally, the environmental conditions for testing should be in a closed environment at 35-2, with humidity greater than 85% and pH values between 6.5-7.2. Additionally, the conditions of the salt spray solution need to be strictly controlled, including sodium chloride solution concentration, spray pressure, and spray volume.

Standards and Judgment

The results of salt spray testing for stainless steel water bottles are important for evaluating their corrosion resistance. Typically, the test results will include corrosion degree, corrosion rate, and corrosion type, among others. Through these results, the corrosion resistance of stainless steel in specific environments can be assessed, providing a basis for its selection and use in practical applications.

The standards for salt spray testing of stainless steel water bottles specify specific requirements for test conditions such as temperature, humidity, sodium chloride solution concentration, and pH value, as well as technical requirements for salt spray test chamber performance. The choice of which salt spray test standard to adopt for the same product depends on the characteristics of the salt spray test and the corrosion rate of the metal and its sensitivity to salt spray.

Methods for judging the results of salt spray testing of stainless steel water bottles include rating judgment, weighing judgment, appearance of corrosion products judgment, and statistical analysis of corrosion data.

In summary, salt spray testing of stainless steel water bottles is an important basis for evaluating the corrosion resistance of stainless steel products. By conducting tests in accordance with relevant standards and specifications, the quality and reliability of wholesale stainless steel water bottles / jugs / bulk coffee cups / vacuum flasks / food containers / insulated mugs / tumblers / double wall dog bowls can be effectively evaluated. Therefore, in the production and quality control process of stainless steel products, the role of salt spray testing should be given sufficient attention to ensure that the products have good corrosion resistance in various harsh environments.