Contents

- 1. What is Delta-E?

- 2. What are the applications of Delta-E?

- 3. Why Delta-E important for water bottle manufacturer?

- 4. How to calculate Delta-E in colors?

- 5. How to digitally check if your custom water bottles match the sample color?

- 6. What does a Delta E less than 2 mean when applied to the color on a water bottle?

- 7. KingStar’s Strict Delta E Control: Ensuring Customized Color Accuracy

- 8. Conclusion

As a leading custom water bottle manufacturer, we receive emails every day from drinkware buyers about custom color questions. In this article, we’re gonna dig into the meaning of Delta-E, how it’s used in customized water bottles, and how understanding Delta-E can level up your sourcing skills. Let’s uncover the secrets of Delta-E and explore its impact on our perception and color choices. Come join us on this captivating journey through color, design, and science!

Color is everywhere in our daily lives, adding so much charm and energy to the world around us. And when it comes to customized water bottles, color becomes a major attraction. Have you ever had that moment where you saw this amazing, uniquely designed water bottle online, only for the color to be completely different when it arrived? This difference in color is what we call color variation, and there’s a really important way of measuring it called Delta-E. Now, Delta-E might sound like some fancy term from the pros, but it actually has a lot to do with our everyday lives. It’s not just some scientific concept; it’s actually a practical tool that helps us understand and measure the differences between two colors. And when it comes to purchasing wholesale custom drink bottles, Delta-E plays a crucial role. By understanding Delta-E better, we can more accurately evaluate and select the products we want, making sure that the colors of our customized water bottles match up with what we expect.

For people buying water bottles and professional procurers, Delta-E is more than just a metric; it’s like a tool to make sure the quality is good. Understanding Delta-E helps them choose colors better, so they can avoid expensive mistakes and keep their brand consistent. Whether you’re getting a few bottles for yourself or thousands for your business, knowing about Delta-E means you have control over the color quality of what you buy, which guarantees satisfaction and professional results.

1. What is Delta-E?

Delta-E, also known as color difference or ΔE, is a technical metric used to describe and quantify the disparity between two colors. It serves as a unit of measurement for perceived color differences by the human eye in a uniform color space. In simpler terms, Delta-E gauges the magnitude of variation between two hues, reflecting the accuracy of color representation. A smaller Delta-E value indicates minimal divergence between the two colors, signifying higher color fidelity. If you are water bottle buyers and procurement professionals, mastering Delta-E becomes crucial as it allows you to ensure that the colors of your water bottles / wholesale stainless steel tumblers / insulated coffee cups / vacuum flasks / can coolers / jugs / vacuum food containers / pet dog bowls accurately match your brand identity or personal preferences. By utilizing Delta-E measurements, you can confidently select hues that closely align with their vision, enhancing the overall quality and consistency of their product line. To further explore the color delta-E of water bottles, please continue your reading.

2. What are the applications of Delta-E?

Before we dig into the importance of Delta-E in the world of personalized drink bottles, it’s worth exploring how widely this metric is used in different industries. Delta-E finds applications across multiple industries due to its ability to accurately measure color differences.

In the printing industry, Delta-E is crucial for evaluating the color accuracy between printed materials and the original design. For instance, if a design featuring a specific shade of red appears slightly orange in the final print, the Delta-E value would indicate this discrepancy. Printers rely on this metric to fine-tune their printing parameters, ensuring color fidelity to the original design.

In the textile industry, Delta-E plays a significant role in assessing color consistency across different batches or materials. Manufacturers use Delta-E to quantitatively evaluate if fabrics of various batches or compositions exhibit color uniformity. A Delta-E value within an acceptable range (typically below a certain threshold) confirms that the colors of these fabrics are consistent, meeting quality standards.

For electronic displays, Delta-E serves as a valuable metric for consumers when selecting monitors or screens. A display with a lower Delta-E value offers superior color reproduction, faithfully rendering images and videos as intended. Monitors with a Delta-E value less than 2, for example, are considered to have excellent color accuracy, providing viewers with an enhanced visual experience.

3. Why Delta-E important for water bottle manufacturer?

Beyond its traditional applications, Delta-E plays a crucial role in the water bottle manufacturing industry. Understanding Delta-E is essential for you guys who are looking to buy or get high-quality water bottles because it ensures that the colors are accurate, consistent, and authentic to the brand. More details will be shown as follows:

Color Consistency and Quality Control

- Delta-E measurement ensures that the color of metal sports bottles remains consistent from batch to batch.

- It helps manufacturers maintain a high level of quality control by objectively measuring color differences.

Brand Identity and Recognition

- Consistent color of personalized sport bottles is essential for branding and customer recognition.

- Delta-E allows manufacturers to produce water bottles that match their brand’s specific color palette, reinforcing brand identity.

Customer Satisfaction

- Customers often associate specific colors with certain brands or product lines.

- Accurate color reproduction, ensured by Delta-E measurements, can enhance customer satisfaction by meeting their expectations.

Regulatory Compliance

- In some industries, such as food and beverage packaging, there may be regulatory standards for color and material safety.

- Delta-E can help ensure that water bottles comply with these standards by providing precise color measurements.

Marketing and Advertising

- Vibrant and consistent colors can make a product more attractive to consumers.

- Delta-E measurements ensure that advertising and marketing materials accurately represent the actual product color, leading to fewer customer complaints and returns.

The concern about Delta-E isn’t limited to custom water bottle makers. As a water bottle buyer or specialized procurement agent, understanding and leveraging Delta-E not only enhances the customer experience but also helps you comply with regulatory standards and effectively market your products. Make Delta-E your ally in sourcing top-notch water bottles that meet your exacting standards. Click and read more: How to Purchase Custom Color Water Bottles

4. How to calculate Delta-E in colors?

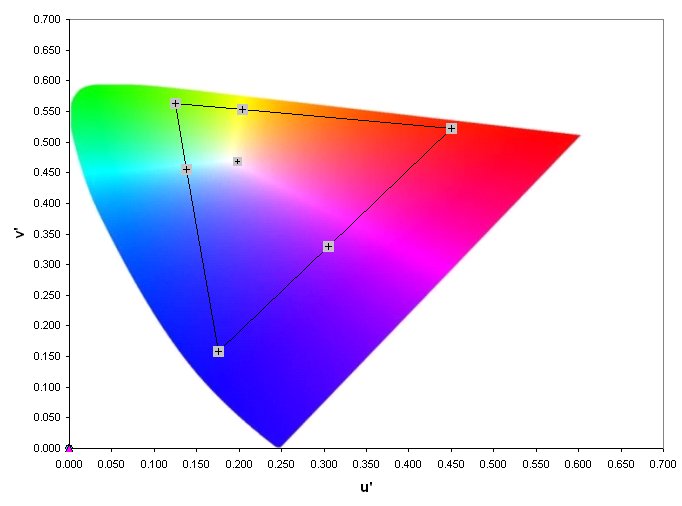

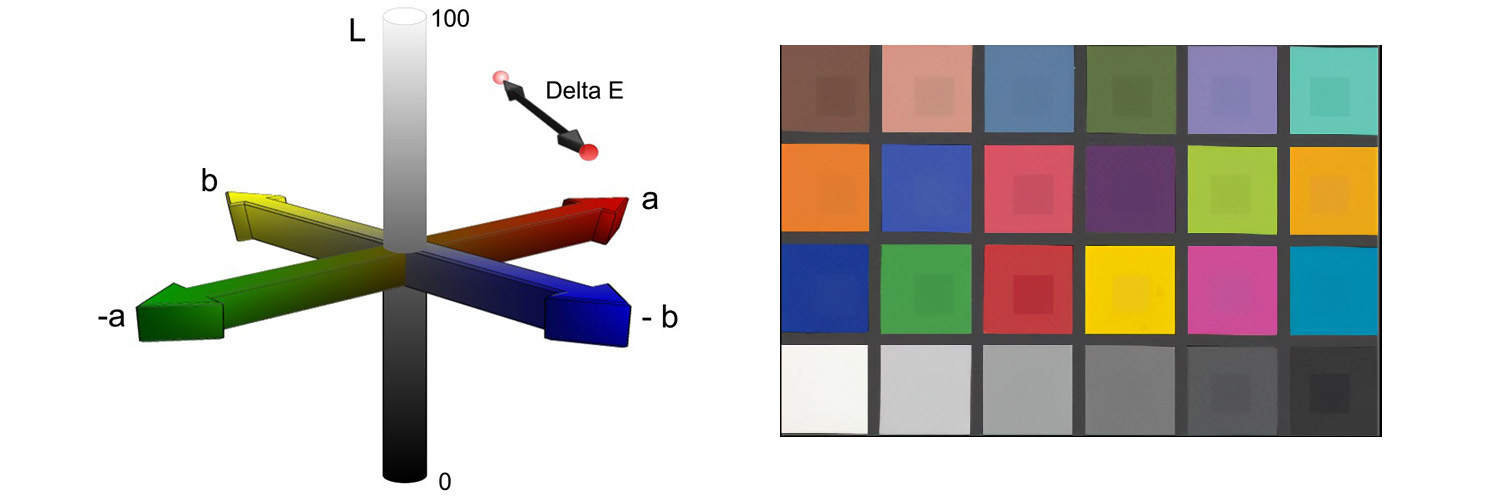

The computation of Delta-E involves three dimensions from the CIE Lab color model: Luminance (L*), red-green chromaticity (a*), and yellow-blue chromaticity (b*). The precise formula for calculating Delta-E is as follows:

E* = sqrt((L2 – L1)^2 + (a2 – a1)^2 + (b2 – b1)^2)

Small changes can significantly affect Delta E values:

- A low Delta E shows little color variation.

- A higher Delta E indicates a bigger color difference.

- Some showing a Delta E of 1 on close look.

- A Delta E of 5 is easily noticeable.

Generally, a Delta E of 1 might be detectable on close inspection, while a Delta E of 5 is easily discernible. Through the use of Delta-E, color disparities between samples can be accurately quantified, providing an invaluable tool for objective color variation measurement. This is especially critical in fields like graphics design, printing, and display technology, where color accuracy and consistency are essential. If you’re looking for customized drink bottles, it’s important to really focus on the Delta-E results. They’ll make sure that your orders are top-notch quality. Click and read more: 4 Best Smart Water Bottles

5. How to digitally check if your custom water bottles match the sample color?

Procurement personnel must be extremely careful when purchasing drink bottles. In addition to relying on the naked eye to discern color differences in customized water jugs, it is more important to learn how to use Delta-E, a scientific tool, to more accurately inspect product quality. This not only affects the aesthetics of the product but also directly impacts the brand image and consumer experience. Next, we will introduce in detail how to use Delta-E to ensure the consistent color and superior quality of the water bottles you purchase.

Ensuring color consistency between a customized water bottle and a sample is crucial, especially in branding and product quality control. To achieve this, a meticulous process involving specialized tools and techniques is required. A general process will be shown as follows:

Required Tools

- Color calibration card or standard color swatch.

- Spectrophotometer (color measurement instrument).

- Adequate light source.

- Notebook and pen.

Preparation

- Ensure you have a color calibration card or standard color swatch with the exact color code of the desired water bottle color.

- Prepare a spectrophotometer, a scientific instrument that can measure the surface color of objects and provide a digital description of the color.

- Set up a detection area under an adequate and uniform light source to ensure measurement accuracy.

Measuring the Sample Color

- Use the spectrophotometer to measure the color of the sample water bottle. Align the instrument with the bottle surface, press the measurement button, and record the results. These results are usually represented by Lab color space values (L*, a*, b*).

Measuring the Customized Water Bottle Color

- Measure the color of your customized water bottle using the spectrophotometer in the same way and record the Lab values.

Comparing Color Data

- Compare the Lab values of the sample water bottle with those of the customized water bottle. Ideally, these values should be very close.

- Calculate the Delta E (ΔE) between the two sets of data, which is a mathematical indicator that measures the difference between two colors. You can use an online Delta E calculator, or if you have professional color management software, it usually includes this function.

Judging Color Consistency

- Set an acceptable ΔE range based on industry standards and your specific requirements. For example, in some industries, a ΔE less than or equal to 2 may be considered color consistent.

- If the ΔE value between the customized water bottle and the sample water bottle falls within the acceptable range you have set, then the colors can be considered consistent.

- If the ΔE value exceeds the acceptable range, there may be significant color differences, and you need to communicate with the supplier to resolve the issue.

Notes

- Ensure a stable measurement environment to avoid external light changes affecting the measurement results.

- Before measuring, make sure the spectrophotometer is calibrated to ensure measurement accuracy.

- If possible, take multiple measurements and calculate the average to reduce errors.

Possible Problems and Solutions

- Problem: The spectrophotometer gives unstable readings.

- Solution: Ensure the instrument is calibrated, check for external light interference, or try measuring in a more stable environment.

- Problem: The ΔE value exceeds the acceptable range.

- Solution: Communicate with the supplier to understand the reasons for color differences and request re-manufacturing or adjustment of the color formula.

Through rigorous measurement and comparison processes, you can make procurement decisions with more confidence, ensuring that each batch of water bottles meets your high-quality standards.

6. What does a Delta E less than 2 mean when applied to the color on a water bottle?

If you are checking the purchasing drink water bottles’ quality, the Delta E value serves as a reliable indicator of color accuracy. A Delta E less than 2 guarantees that the personalized water bottles you procure not only meet your color specifications.

Perceptibility of Color Differences

- When Delta E is less than or equal to 1 (ΔE ≤ 1), the color difference between the measured sample and the standard sample is so subtle that it is almost imperceptible to the human eye. This level of color matching is considered excellent and suitable for high-end or critical color applications where precise color reproduction is essential.

- In the case of 1 < ΔE ≤ 2, there is a slight but noticeable color variation. However, this difference is typically within acceptable tolerance limits for most applications, including water bottles, unless specific customer requirements state otherwise. The human eye might be able to detect some minor differences under close inspection, but these are generally not considered objectionable in most cases.

Quality Control and Customer Satisfaction

he production of personalized water bottles needs to maintain a Delta E less than 2, so that buyers can be assured that the final product meets the required color standards and satisfies customer preferences. By ensuring consistency across production batches, you can minimize potential color variations and reduce the chances of customer dissatisfaction. Moreover, having a Delta E within this range demonstrates our commitment to strict quality control, highlighting your dedication to precise and uniform colors.

7. KingStar’s Strict Delta E Control: Ensuring Customized Color Accuracy

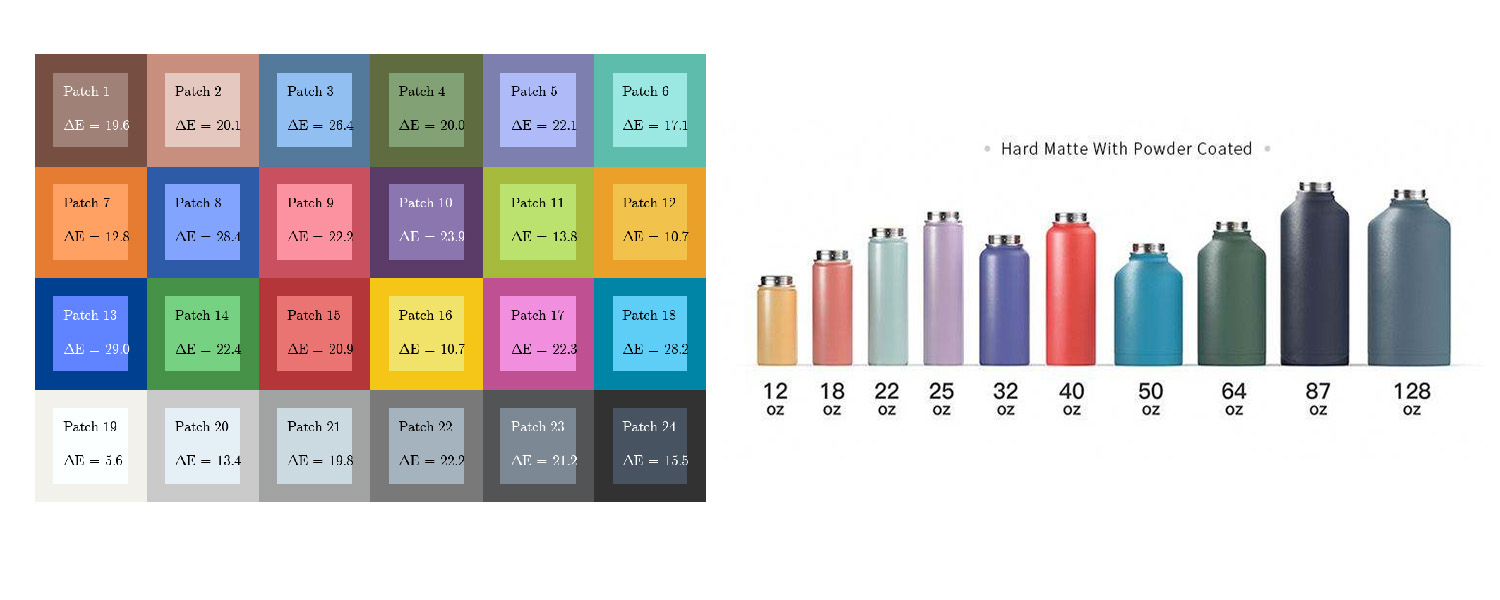

As a top company in the water bottle manufacturing industry, every time we’re about to launch a new colored water bottle or meet our customers’ customized color requests, it’s crucial for us to make sure that the actual color matches the sample provided by the designer. To measure this color consistency, KingStar usually uses Delta-E for evaluation. The examples below are from our production process of ensuring customized color accuracy:

| Lab Values of Sample Water Bottle Color: | L=50, a=10, b=20 |

|---|---|

| Lab Values of Produced Water Bottle Color: | L=52, a=12, b=21 |

| Delta-E Calculation: | ΔL = 52 – 50 = 2 Δa = 12 – 10 = 2 Δb = 21 – 20 = 1 |

| Delta-E Value: | ΔE = [(2)^2 + (2)^2 + (1)^2]^0.5 ≈ 2.83 |

| Conclusion: | Due to the Delta-E value exceeds 2, the produced water bottle needs subtitle adjustments, so as to meet the design requirements. |

Example One: Comparing Sample Color with Production Color

| Lab Values of First Batch Water Bottle Color: | L=75, a=-5, b=15 |

|---|---|

| Lab Values of Second Batch Water Bottle Color: | L=75, a=-4, b=16 |

| Delta-E Calculation: | ΔL = 75 – 75 = 0 Δa = -4 – (-5) = 1 Δb = 16 – 15 = 1 |

| Delta-E Value: | ΔE = √[(0)^2 + (1)^2 + (1)^2] ≈ 1.41 |

| Conclusion: | With a Delta-E value less than 2, the produced water bottle color is nearly identical to the sample color, indicating a high level of color accuracy in the manufacturing process of this batch of drink bottles. |

Example Two: Comparing Colors Between Different Production Batches

| Lab Values of Standard Water Bottle Color: | L=40, a=30, b=-10 |

|---|---|

| Lab Values of Suspected Non-conforming Water Bottle Color: | L=45, a=32, b=-8 |

| Delta-E Calculation: | ΔL = 45 – 40 = 5 Δa = 32 – 30 = 2 Δb = -8 – (-10) = 2 |

| Delta-E Value: | ΔE = [(5)^2 + (2)^2 + (2)^2]^0.5 ≈ 5.48 |

| Conclusion: | Due to the relatively large Delta-E value, there is a noticeable color difference between this water bottle and the standard, which classifies it as a non-conforming product. |

Example Three: Detecting Non-conforming Water Bottles

KingStar is super strict about overseeing every single step of making custom mugs. We know how important it is to get the colors just right for our clients. If a custom mug doesn’t meet the standards, we take quick action by getting rid of the defective one and fine-tuning our equipment so that we can consistently deliver top-notch quality. Our commitment is to make sure that every drink bottle we produce not only meets but exceeds customer expectations, guaranteeing satisfaction every single time.

8. Conclusion

In the world of custom-colored water bottles, Delta-E plays a crucial role. It’s like the ultimate standard for making sure the colors are right and meeting your exact expectations. When it comes to creating a personalized drink bottle, it’s not just about the final product; it’s about every step of the process – every little detail and every careful measurement of color matters. At KingStar, we really understand this. With our extensive experience, skilled team, and top-notch equipment, we take pride in offering unbeatable quality control for each unique water bottle we make. From precise color adjustments to using spectrophotometers to measure colors accurately, everything we do is carefully calibrated to ensure you’re satisfied. We know how important it is for colors to be consistent, and with our attention to detail, KingStar guarantees that every buyer and procurement specialist will receive a metal bottle that goes beyond their expectations. Connect with KingStar for all your custom water jug needs; we’re dedicated to achieving color perfection. If you have any further questions or inquiries, please don’t hesitate to reach out!