Stainless steel water bottles remain popular in various markets, being seen in individual purchases, corporate gift-giving and so on. However, when you search for keywords like “stainless steel hip flask” on retail platforms such as Amazon and eBay, you will find a large number of related products with significant price variations. This has led many consumers and buyers to start questioning the actual production costs behind these products. Are those low prices due to poor quality? Then are the higher prices due to a brand or other premium?

Understanding the various factors that cause cost differences (from material selection to production methods, etc.) is crucial for making informed purchasing decisions. This article provides a clear analysis of the global market price landscape and explains the significant advantages of factory direct sales models in terms of cost and customization.

Market Overview: Global Price Range

Products of the same specification may range from $10 to $50 in retail prices on those e-commerce platforms, while bulk purchases are slightly cheaper but usually cost $5 to $30 per item. But from the product description, it’s not clear what makes these similarly appeared products price so differently.

However, when we examine the upper supply chain – manufacturing process, we will discover a completely different pricing model. By directly collaborating with the water bottle original manufacturing factory like KingStar, consumers or purchasing agents can obtain more competitive prices. For standard 304 stainless steel basic products, large-scale orders can reduce the unit cost to only $0.3 to $1 per piece. Even for custom products with logo engraving or special surface treatments, the cost per piece is usually as low as $0.5 to $3. It is worth noting that some manufacturers have begun to accept smaller minimum order quantities, which creates valuable opportunities for start-ups and small retailers.

Six key factors ultimately determine the final unit price:

- Material (Stainless steel grade 304 vs. 316)

- Polishing method (e.g., mirror, brushed, or sandblasted finish)

- Coating or exterior wrap (PU, leather, etc.)

- Packaging type

- Logo engraving or other customizations

- Order quantity

The following section will analyze the specific costs based on the materials and production process. While to gain a more comprehensive understanding of the cost factors, you can read this post: How Much Does It Cost To Manufacture A Stainless Steel Water Bottle? Although it mainly focuses on the manufacturing cost of the water cups, some common factors within it can still serve as references.

Common Manufacturing Materials & Processes

To know how to maximize cost savings without compromising quality, one must first delve into the manufacturing process and understand the major components of manufacturing costs – materials and production methods.

Material Grades

- 304 Stainless Steel($0.005 / g): Food-grade, rust-resistant, and the most widely used for quality flasks.

- 316 Stainless Steel($0.006 / g): High-end, with superior resistance to saltwater and chemicals; ideal for marine or premium use but costs more.

Production Steps

The manufacturing of stainless steel kettles follows a precise production process, which directly affects the quality and cost of the product. The production process begins with the stamping stage, which is the first critical step. Using large stamping machines and precise molds, the flat stainless steel coil material is repeatedly stretched and stamped to form the three-dimensional prototype of the kettle body. The cost of this part mainly consists of raw materials and molds. Most of the raw materials use 304/316 stainless steel, with a thickness typically ranging from 0.4 to 0.6 mm. The material price varies according to market fluctuations, and material loss is also a consideration. The initial investment in mold costs is high, but it is spread out over mass production. The larger the batch, the lower the proportion of the cost allocated to the molds. The next stage is the welding stage, where advanced laser welding technology is used to achieve seamless and smooth connections. The cost of this stage is mainly influenced by technical equipment and process level. The flasks then undergo polishing with 300 to 400# abrasive materials to obtain a smooth surface texture. Usually, starting from rough polishing (such as 300-400# grinding wheels or belts), higher numbers (such as 600#, 800#) are used for fine polishing. It is recommended to cooperate with producers with high quality and automation levels to avoid high labor costs and inconsistent polishing effects. Optional surface treatment methods include various coatings, electroplating, or decorative packaging, and the cost varies depending on the process. Each unit must pass strict airtightness tests before entering the final packaging stage. Defective products detected during the test mean that the raw materials and processing costs of all previous processes are lost. Therefore, this stage is the key checkpoint for controlling overall cost losses. The final packaging form can range from simple bulk packaging to custom gift boxes, and the automation level of the packaging line also affects the packaging speed and labor costs.

To illustrate more intuitively, here are three typical configurations we regularly produce, all available under $3 per unit:

First is an economy promotional model. In this model, we utilize durable 304 stainless steel with a fine brushed finish that effectively conceals minor scratches. The flask receives clean silk-screen printing for logo application and comes with a basic PU sleeve. Packaged in individual poly bags, this option has become our most popular choice for event giveaways and corporate promotions, with clients typically ordering 5,000+ units per batch, with unit cost $0.3-1.

Next up is another type of project requirement that we frequently receive: standard retail model featuring 304 food-grade stainless steel with a uniform mirror polish and average unit cost $0.5-2. The manufacturing includes precise laser engraving for brand logos and an electroplated finish in popular colors like black matte or champagne gold. Each unit comes with an enhanced PU leather wrap and is presented in a custom cardboard gift box. This model has proven to be effective for beverage brands and specialty retailers, with the order quantities typically ranging from 1,000 to 3,000 units.

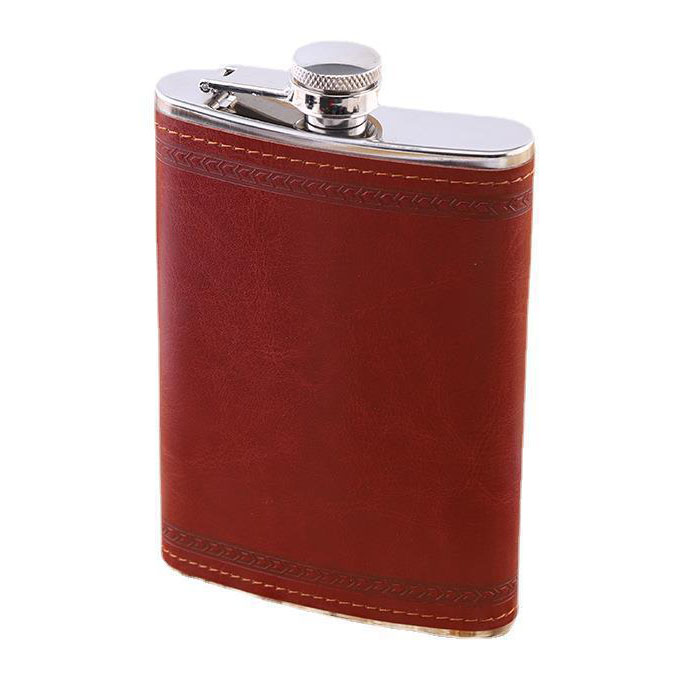

Finally, there is the upgraded gift version, with a slightly higher unit cost ranging from 1 to 3 dollars. Our mid-to-high-end product line uses 304 stainless steel material within this price range and undergoes multi-level mirror polishing treatment. For example, there are wine bottles with fine laser engraving, double-color filling, and are packaged in high-quality PU leather, with the leather surface precisely sewn. The complete set includes a safety material-made drinking cap and a beautiful gift box packaging. This version is very popular in craft spirits brands and corporate gift projects, and the usual order quantity is between 800 and 2000 units.

KingStar’s Production & Pricing Advantage

Here at KingStar, we pair cutting-edge manufacturing tech with tight quality control steps to make stainless steel water bottles that hit international standards, and still keep prices competitive.

Quality’s our top priority, and it starts right at material pick: we use 304 food-grade stainless steel as our standard base. That choice makes sure the final bottles are safe to use, plus tough enough to last. For the making process, we rely on automated welding for the structure and uniform polishing for the surface. This way, every bottle turns out consistent in both quality and appearance.

On top of that, we’ve got all kinds of customization options for you. Think PU or real leather covers, precise laser engraving (for logos or designs), and even custom-made lids. Whatever different brands or users need, we can tweak things to fit.

Briefly, when it comes to pricing, our structure is designed to accommodate different needs and budgets similar to above described:

For high-volume orders, our standard 304 stainless steel flasks (6-8 oz) are priced between $0.3 and $1 per unit; For Mid-range models, which include enhanced polishing and basic engraving or other simple customization, range from $0.5 to $2; For premium configurations, such as those customized materials, complex patterns, decorations, fitted with leather wraps, and paired with gift box packaging-prices typically fall between $1 and $3 per piece.

There are several compelling reasons to choose KingStar as your flask supplier. We welcome both small and large orders with our low minimum order quantity (MOQ) policy. Full customization is available, not only for the flask itself, but also for logos, packaging, and material finishes. See our custom capabilities at Custom Molding, Custom Logos, Custom Decorating and Custom Packaging. Our reliable supply chain can ensure a stable delivery cycle and reliable product quality. To achieve this, we have conducted rigorous tests. Each product undergoes separate leakage and pressure tests before being shipped.

Summary & Buyer Tips

Shopping on online market is indeed convenient and fast, but its product prices include multiple circulation links, and that add up prices, from the platform, middlemen, and sellers. However, if you purchase goods directly from the factory, you can get a fair price and also ensure that the quality of the goods will not be compromised.

Before placing an order, please remember the following points:

- First off, materials: Always double-check the steel grade (like 304 or 316) – it makes a big difference for safety and durability.

- Next, finishing and polishing: Higher polish levels or other additional finishing steps can affect cost, so be clear on what you need.

- Samples matter: Always check a sample first to make sure the quality works for you before you lock in a bulk order.

- Total cost: Don’t just look at unit price, instead you should add in any customization fees to get the full picture.

Whether you need flasks for events, retail shelves, or branded swag, KingStar’s got you covered: factory-direct prices (between $0.3 and $3 per piece), consistent quality, and full support for custom tweaks. Want a custom quote? Just reach out to the KingStar team today at sales@waterbottle.tech with your specs: size, material, finish, how many you need, and we’ll hook you up with a competitive bulk price that fits exactly what you’re looking for.