Users who have used laser etching machine should notice that different parameters or accessories will mark different depth even if you are using the same machine to mark on the same water bottle cup.

Actually laser-etching depth can be adjusted to a certain extent, but not all products can have the desired depth, which needs a coordinate interaction among each condition. Now comes the question – how can a laser etching machine mark our expected depth? Here KingStar will detail these steps for you:

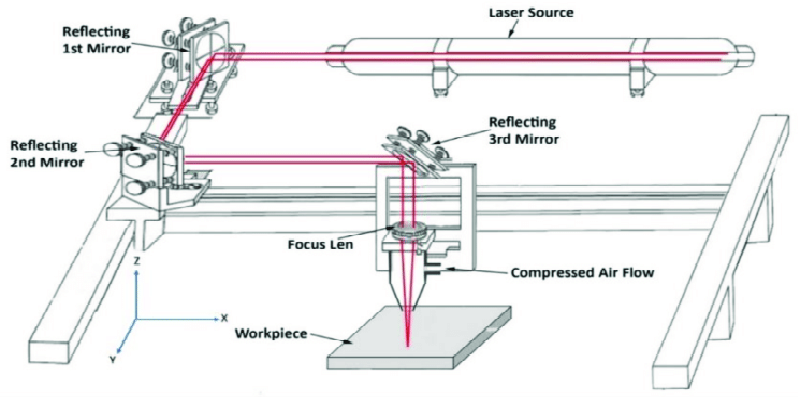

- Enhance the power capacity of laser: The laser is the core component of the machine. If its power capacity is improved, the laser beam will inevitably be intensified and the depth will increase.

- Replace the field lens of the laser marking machine with a small-range one and then you’ll get deeper marking. For example: the standard field lens of 170×170 (mm) can be changed in to the one of 110×110 (mm).

- Slow down machine’s etching speed while other parameters remain the same. Slower engraving marks deeper.

- Equip the machine with better accessories. A high-quality laser group will be a good way to treat lens flares. A better beam expander helps the laser more focused.

- Repeated marking: After multiple marking, the deeper marking you can get in the same place.

If you need deeper marking on bulk water bottles / stainless steel tumblers, laser engraving machines with famous brands will be your best choices. Top brand’s laser machines, featuring with high engraving precision, good stability, can be used for the crafting of many materials like hardware products, precision instruments, mold steel, common metals and alloys (iron, copper, aluminum, magnesium, zinc and other metals). In addition, they can be utilized of a large scope, especially suitable for large-area engraving as well as deep engraving processing for varied complex patterns.

As a leading wholesale water bottle manufacturer, KingStar has some warm tips for you here. When buying a laser marking machine for your water bottle custom engraving business, you must have a full understanding to the surface of vacuum insulated stainless steel drinkware. What are the requirements and long-term plans are? For example, the desired depth of the blank water bottle is shallow now but you may need deeper marking in the future. Because the laser equipment with deep marks can have shallow etchings by setting the relevant parameters but the laser equipment for shallow marks cannot do that by only adjusting parameters. Therefore, you have to change accessories to improve machine’s performance. Then your cost naturally get higher. So why not purchase the machines with deepest configuration at beginning!

Insulated Metal Tumbler 20 oz

$2.15-$3.16

Insulated Tumbler 30 oz

$2.59-$3.90

Tumbler with Straw 18 oz

$3.25-$3.95

Insulated Rambler Mug 14 oz

$5.51-$6.31

Narrow Mouth Bottle 500ml

$3.22-$3.46

Wide Mouth Bottle 32oz

$3.98-$4.83

Cola Shaped Bottle 18 oz

$3.05-$3.26

Thermos Milk Bottle 17 oz

$3.05-$3.46