People who have used laser engraving machines know that the challenge of focus adjustment in inevitable during period use.

Every time KingStar will emphasize the importance of focal length adjustment when providing technical support to customers. Because you need to adjust the parameters first (different stainless steel water bottles / blank tumblers / plain cups / flasks / mugs, different models or different marking effects have different marking parameters) in the marking process so as to achieve the expected marking effect. Focal length is the key part for adjusting the machines. To perfectly mark the high-quality logo, the focal length must be set at a certain distance.

There are many ways for focus. Do you know what they are? Then you can take a look at these methods with KingStar:

1. Focal length measurement

Ask the equipment manufacturer for current focal length data of the machine and then record it. By this way, each time when you change the product, you can directly lean a steel ruler on its surface and shake it up and down to the scale data according to a certain referred surface on the field mirror. This method is suitable for all laser marking machines, but it can’t be applied when the position of the product required for laser marking is concave or the steel ruler can’t be stuffed into. In this case, focal length measurement is not practical at all.

2. Continuous laser testing

Draw a square or circle of about one centimeter on the marking software, scale up the laser energy to a relatively large extent in the setting parameter column after conventional filling, during which low frequency is usually used. Then do the ordered step as follows: place the stainless steel water bottles/ blank tumblers / plain cups / flasks / mugs etc at the marking position, tick the “continuous marking”, click “continuous processing” and “marking” and shake the handle to adjust the up and down of Y-axis for several times to find the appropriate focal length. The position of focal length can’t be ensured until the laser has strongest energy, clearest sound and brightest color on the stainless steel water bottles / blank tumblers / plain cups / metal flasks / wholesale mugs /bulk jugs etc.

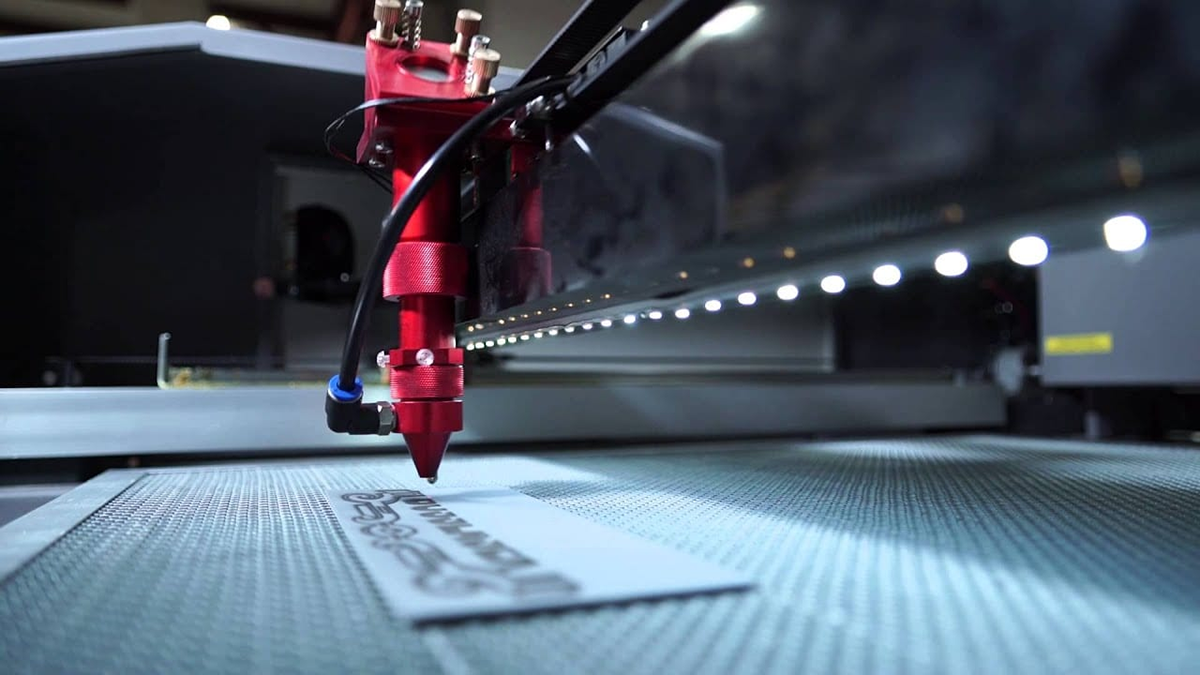

Laser Engraving Custom Logo on Blank Water Bottles

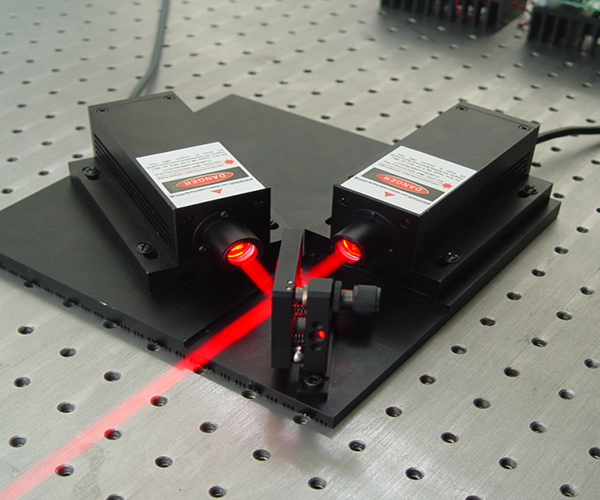

3. Get value by the alignment of two red lights

This method requires the equipment itself to have this hardware configuration while leaving the factory. Install one or two oblique red light next to the galvanometer or galvanometer and use some principles of the right triangle tofind the other right angle edge of the plane where the focal length is located by a fixed right angle edge and two coincident hypotenuse edges. You can quickly find the focal length by shaking up and down until the two red light points coincide. Although this method is convenient and fast, it needs the equipment manufacturer to be equipped with this device. And it is easy to misleading operator to form a wrong focal length surface without proper adjustment.

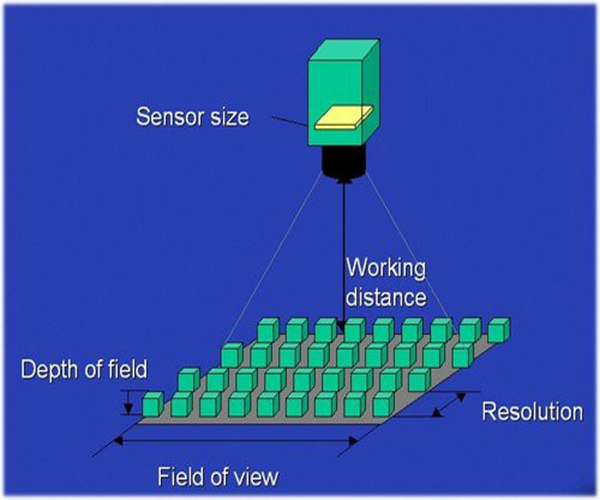

4. Auto-focus system

Automatic focusing system can be configured for any laser marking equipment. Just install an auto-focus system on the original laser equipment and realize automatic focusing and marking through it. Auto-focusing can be realized even if there is a slight difference in the thickness of the stainless steel water bottles / blank tumblers / plain cups / flasks / mugs.

After the laser marking machine is equipped with an auto-focus system, you no longer have to worry about the problem of focal length!

Insulated Metal Tumbler 20 oz

$2.15-$3.16

Insulated Tumbler 30 oz

$2.59-$3.90

Insulated Rambler Mug 14 oz

$5.51-$6.31

Wide Mouth Bottle 32oz

$3.98-$4.83

Cola Shaped Bottle 18 oz

$3.05-$3.26

Conclusion

The above can be summarized as follows: focal length measurement, continuous laser testing and get value by the alignment of two red lights all belong to manual focus with the features of slow speed, low efficiency, and unguaranteed focus accuracy. However, auto-focus system features with fast speed and high focus accuracy.

KingStar engineers kindly remind you that “continuous processing” is only used when focusing. Please remember to turn off “continuous processing” and continue operation after focusing.

As a top wholesale blank stainless steel water bottle manufacturer for laser engraving business, KingStar provide quality metal drinkware as well as technical support. At any time, as long as you encounter difficulties in the use or maintenance of laser marking machines and need technical support, please feel free to contact us at sales@waterbottle.tech.