There is an indisputable fact: product quality is far more convincing than marketing promotion. As far as the water bottles are concerned, some of them have a “high-end texture” just by looking at the appearance, while others show a “cost-effective choice” in a low-key way, while others are silently telling that “it should have cost more at the beginning”. For those B 2B purchasers who want to strictly control the cost profit rate and adhere to strict quality standards, choosing the right material grade of stainless steel is not just a simple procurement work, but a strategic decision that must be carefully considered.

In all kinds of material-related questions asked by the purchasing department, we found that 201 stainless steel caused more misunderstandings than expected. Although its price advantage is attractive, there are many hidden dangers in actual performance. Many B2B purchasing teams often wait until the product is mass-produced, and some even realize it after receiving customer feedback and paying a painful price. Based on years of experience in the water bottle manufacturing industry, this paper will deeply analyze the real advantages and limitations of 201 stainless steel for large-scale procurement scenarios.

What Are the Key Differences Between 201, 304, and 316 Stainless Steel?

Many cost-driven buyers’ first encounter with 201 stainless steel is full of optimistic expectations. After all, it looks fine at first glance, and offers immediate budget savings. But the chemistry behind all three materials reveals why 201 would behave differently in manufacturing and real-world use.

Let us break it down for you.

| Steel Grade | Chromium % | Nickel % | Carbon % | Food Grade Status |

| 201 | 16–18 | 3.5–5.5 | ≤0.15 | Not recommended |

| 304 | 18–20 | 8–10.5 | ≤0.08 | Yes (18/8 standard) |

| 316 | 16–18 | 10–14 | ≤0.08 | Yes (marine grade) |

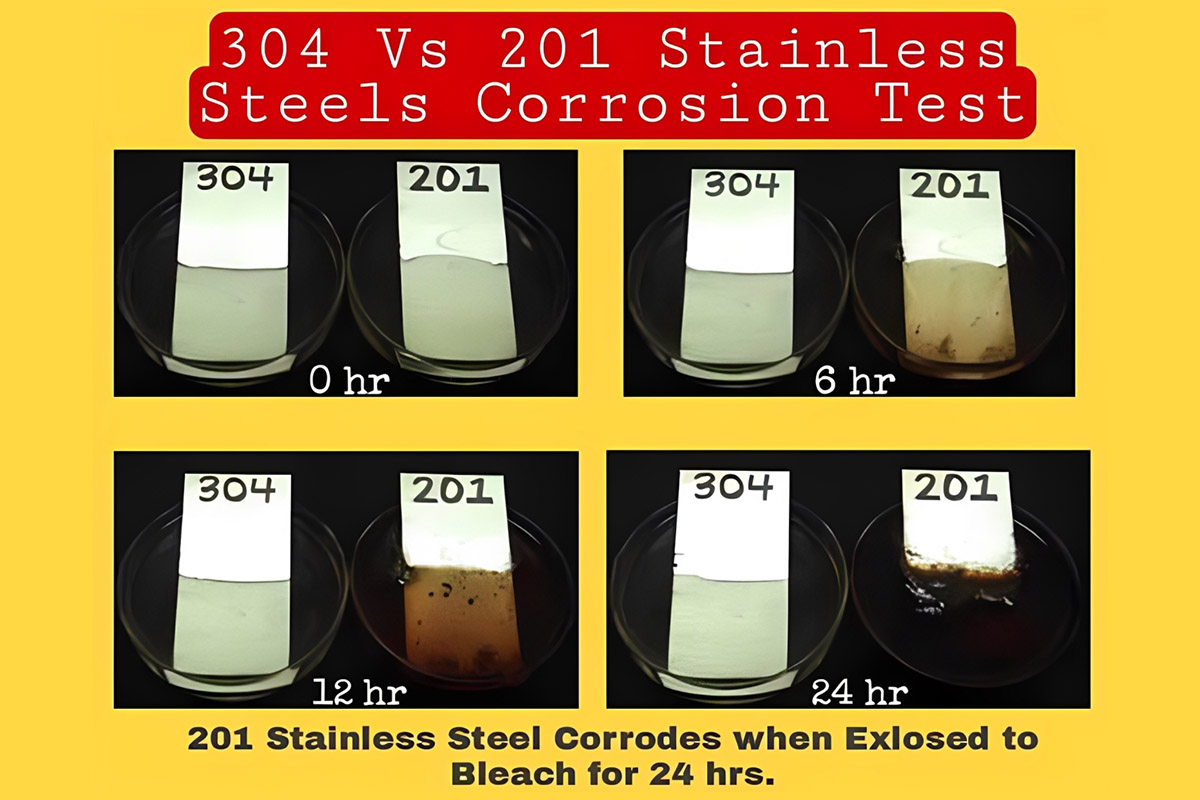

The fundamental problem lies in the proportion of elements. The content of chromium and nickel in 201 stainless steel is low, and it is easy to be corroded by chemicals, especially by acids, which leads to the continuous decline of surface stability. In the production process, this kind of material difference will immediately appear, especially when compared with other stainless steels. It is more difficult for 201 stainless steel to be processed into different shapes, because this difference in composition ratio will make the material itself harder and tougher, and the machining fault tolerance rate is extremely low. In our early production process, we counted a set of outstanding bad data: compared with 304 stainless steel cup, the bad rate of 201 stainless steel cup is nearly 15% higher, and the defect problems focus on cracking, uneven forming and uneven surface.

201 stainless steel welding process also requires higher precision. Its low nickel content will enhance the heat sensitivity of the material, not only slow down the production process, but also increase the labor cost. Even after successful molding and welding, the surface finish of the 201 stainless steel cup fades much faster than that of the 304 stainless steel cup, which means that the texture of the final product is often rougher, especially after repeated use or cleaning.

In a word, the price of 201 stainless steel is in line with the budget, but it is difficult to meet the requirements of large-scale B 2B orders for product appearance consistency and structural stability.

Explainer Video: Material Guide for Water Bottle Tumbler Cup

Which Stainless Steel Grade Is Safest for Food and Drink Contact?

Regulatory compliance is another factor that is keeping 201 stainless steel away from the industry. Although it is used majorly for decorative and no-contact metal products, it does not meet the international food-grade standards for drinkware.

We have summarized some key regional requirements and 201 steel performance into this chart below.

| Region | Standard | Key Requirements | 201 Steel Status |

| United States | FDA CFR 21 | Minimum stability + no harmful migration | Fails consistently |

| European Union | EC 1935/2004 | No health risk to consumers | Requires testing, often fails |

| Australia | FSANZ | Food-safe materials only | Not approved |

| Japan | JHOSPA | High purity, corrosion resistance | Insufficient nickel |

304 stainless steel can easily meet the relevant standards, so it has been recognized by mainstream retailers all over the world. Like us, many B 2B buyers were surprised to find that 201 stainless steel is not a food-grade material, which has a great impact on product compliance.

We have seen too many cases like this: 201 stainless steel products marked as drinking cups were intercepted and detained at customs. One customer’s experience is particularly typical-additional tests show that the metal ion migration of his products exceeds the standard, which eventually leads to the failure of the listing window of the whole retail product. The excessive migration of metal ions is a common problem caused by the low chromium and nickel content in 201 stainless steel.

In addition, the certification and testing institutions have extremely strict audit standards for 201 stainless steel used in food contact products. It is almost impossible for enterprises that need to obtain FDA (American Food and Drug Administration), LFGB (German Food and Commodity Law) or relevant EU certifications to issue a certificates of conformity for 201 stainless steel water cups.

The certainty of product compliance is very important for enterprises engaged in drinking fountains. This certainty comes from 304 and 316 stainless steel, not the regrettable 201 stainless steel.

Click and read more about Custom Options: Custom Bottle Tumbler Decorating, Custom Logos of Water Bottles, Custom Water bottle Packaging

What Is the Cost-Performance Trade-off for 201/304/316 Stainless Steel?

When buyers think about 201 stainless steel, they’re encouraged by the thought of lower upfront material costs. At first glance, 201 can really seem appealing, because its raw material cost is roughly 15–20% lower than 304. However, once it comes to the real-world, where performance, compliance, and after-sales expenses are considered, the financial equation changes drastically.

Comprehensive Cost Analysis

| Cost Factor | 201 (Low-Grade) | 304 (Food-Grade Standard) | 316 (Marine/Medical Grade) | Notes |

| Raw Material | ~80–85% of 304 | Baseline | ~125–140% of 304 | Molybdenum raises 316’s cost |

| Processing & Labor | Similar to 304 but more defects | Standard | Slightly higher | 316 wears tooling faster |

| Quality Control | Higher inspection load | Standard | Standard | 201 requires more testing |

| Estimated Direct Cost | ~85–90% of 304 | Baseline | ~120–135% of 304 | Direct material comparison only |

The hidden cost of 201 stainless steel often puts pressure on buyers. Higher defective rate, customer complaint rate and limited market opportunities will all lead to the overall cost being underestimated. Many corporate customers find that the adoption of 201 stainless steel will hinder them from entering the channels of large retailers, and it is also difficult to meet the compliance requirements of corporate customers. The profit loss caused by limited market alone far exceeds the raw material cost saved in the previous period.

In contrast, the performance benchmark of 304 stainless steel is stable, which can be accepted by almost all markets; The 316 stainless steel can help enterprises to achieve premium pricing in scenarios with extremely high requirements for durability and performance.

Why KingStar Does Not Use SS201 For Manufacturing Water Bottles

Although the appearance of 201 stainless steel is almost the same as that of high-grade stainless steel, it hides the compliance risks, short durability and unpredictable long-term costs. That’s why KingStar, the leading water bottle manufacturer, does not use SS201 for producing reusable metal water bottles / thermos flasks / insulated cups / hip flasks / can coolers etc.

For buyers looking for a reliable water bottle manufacturing scheme, 304 stainless steel is still the general standard in the industry, and 316 stainless steel can provide high-end performance advantages for the demand market.

Choosing suitable materials is not a simple purchasing decision, but a strategic move related to compliance, customer satisfaction and brand reputation. For most enterprises, this means that 201 stainless steel is completely unnecessary to be considered in the material list of drinking fountains.

If you are evaluating the stainless steel options for water cups, or need professional support regarding material selection, compliance standards, or customized manufacturing solutions, then KingStar is always available to assist you.

Our engineering and project team can provide material consultation, mold development, and large-scale production support, all of which meet the needs of global purchasing. You can contact us(sales@waterbottle.tech) at any time to discuss your project requirements and obtain reliable manufacturing solutions.