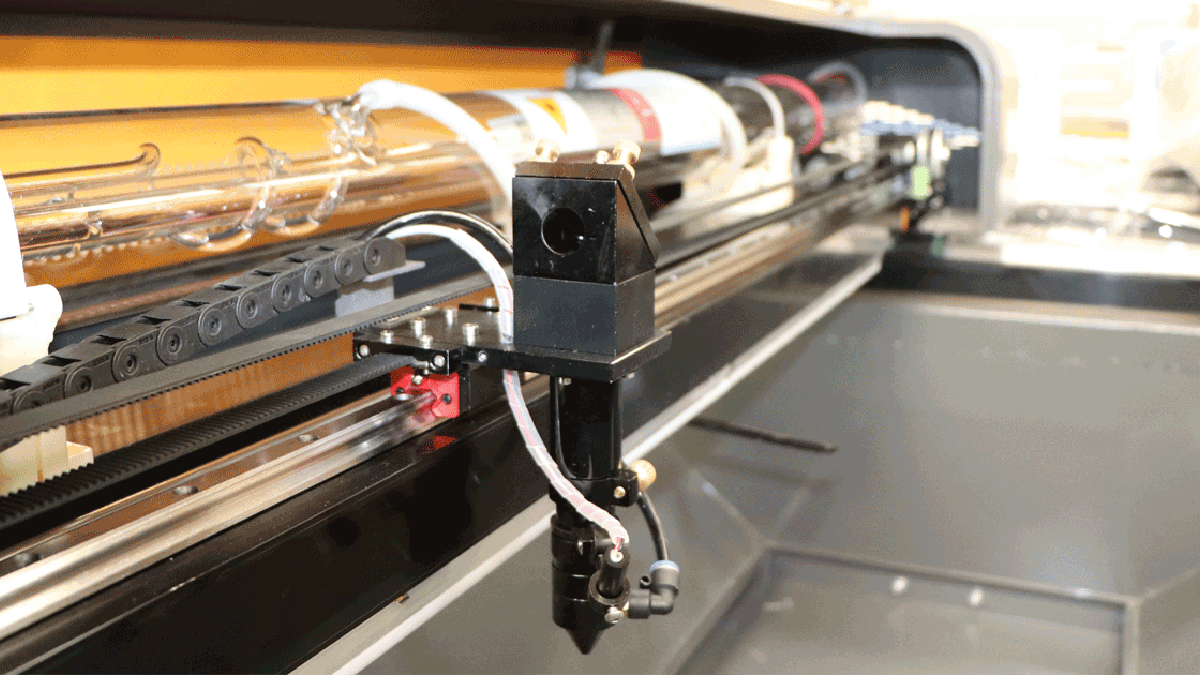

It’s dangerous to operate the CO2 laser marking machine with a laser wavelength of 10.64um improperly. A novice can do that independently after professional training. KingStar with years of custom stainless steel water bottle laser marking experience summarize 16 notices while using CO2 laser etching machines as follows, hoping to help users who are using or preparing to purchase CO2 laser engraving machines.

- Observe safety operation procedures and strictly follow machine’s starting steps while operating. Don’t operate carelessly.

- The machineoperator must be trained, familiar with the structure and performance of the equipment as well as relevant knowledge of operation;

- (PS: KingStar will conduct professional one-on-one training operations for customers.)

- Training method: Centralized teaching and on-site operation demonstration are provided until the customer can operate machine correctly and skillfully to engrave stainless steel drinkware such as insulated bottles, vacuum flasks, wholesale blank metal cups, pet bowls etc.)

- Wear goggles when working and avoid facing the laser beam directly to avoid hurting eyes.

- Engraving machine proof before marking new products. Batch marking of products after achieving goodproofing.

- (PS: If you encounter a problem that cannot be solved by yourself, please contact KingStar and our engineers will provide you with technical support to help you minimize your loss.)

- Don’t engrave the product until you have a clear understanding to its material so as to avoid risks.

- (PS: CO2 laser machine is mainly suitable for the marking and cutting of non-metallic materials like wood, bamboo, acrylic, paper, leather, cloth and stone.)

- The operator shouldn’t leave the post without authorization or entrust untrained personnel to operate when the machine is running. If necessary, stop or cut off the power switch before leaving.

- Keep fire extinguishers within easy reach.

- Turn off the laser when not marking.

- Keep flammables away from unprotected laser beams.

- Stop marking immediately to troubleshoot and then report the faults to supervisor if something wrong happens during processing.

- Keep the site around the equipment clean, tidy and oil-free.

- Keep the internal circulating water of chiller and water tank clean by changing it with deionized or pure water regularly.

- The laser marking area shouldn’t be larger than the working area.

- Don’t touch machine with wet hands for electrical safety.

- During the whole operation of the laser marking machine, it is strictly forbidden to Don’t put your head and hands into the range of the laser scanner to prevent accidental injury.

- Avoid frequent startup and shutdown. Power on at least 3 minutes after shutdown.

Looking for wholesale blank water bottles for your laser engraving business? Send an email to sales@waterbottle.tech, you will get prompt reply within 24 hours.

Insulated Metal Tumbler 20 oz

$2.15-$3.16

Insulated Tumbler 30 oz

$2.59-$3.90

Insulated Rambler Mug 14 oz

$5.51-$6.31

Narrow Mouth Bottle 500ml

$3.22-$3.46

Wide Mouth Bottle 32oz

$3.98-$4.83

Sport Water Bottle 18 oz

$3.12-$3.46

Cola Shaped Bottle 18 oz

$3.05-$3.26

Thermos Milk Bottle 17 oz

$3.05-$3.46