As a custom stainless steel bottle manufacturer, after more than twenty years of deep cultivation in the field of stainless steel cup manufacturing, we deeply realize that the choice of stainless steel brand can determine the success or failure of a production line.

Many buyers take it for granted that as long as the cost of raw materials is reduced by a few dollars, the profit rate can be directly improved. However, they neglected one thing: choosing the wrong material will quietly lower the quality of the product, accelerate the corrosion of the cups, lead to the failure of the product to pass the food safety certification, and ultimately damage your brand reputation. In the many inquiries we have received, the demand for using 201 stainless steel in the production of wholesale water bottles appeared more frequently than we expected. Although this material is attractive to cost-sensitive items, buyers must fully realize its limitations in the application of food contact products.

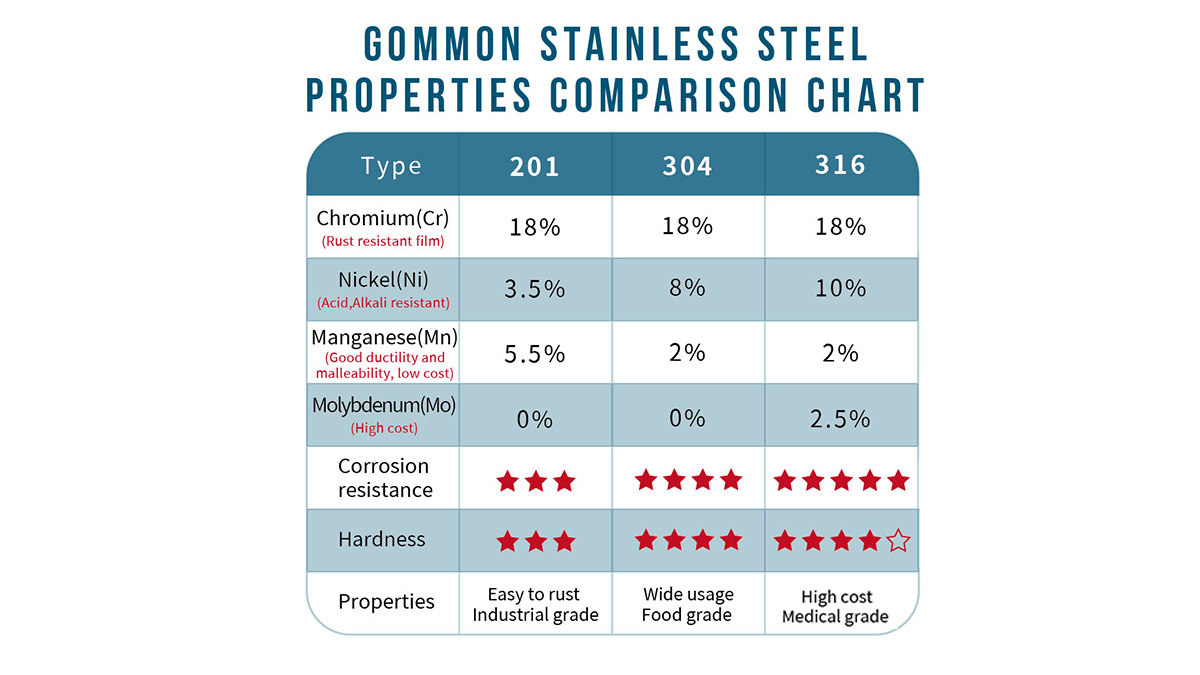

What Are the Main Differences Between 201, 304, and 316 Stainless Steel

For a long time, 304 stainless steel has been the benchmark material in the drinking water appliance industry, with chromium content of about 18% -20% and nickel content of about 8% -10.5%. This ratio makes it have the corrosion resistance, durability and food contact safety compliance on which the brand depends. After upgrading to 316 stainless steel, the performance is even better. About 2% -3% molybdenum is added to the basic formula of Cr-Ni alloy, which makes 316 stainless steel have better pitting corrosion resistance and can also withstand salt spray and acid environment corrosion. 316 stainless steel is the reliable first choice material in industries such as ships, medicines and medical equipment, and no faults are allowed in these industries.

In contrast, 201 stainless steel belongs to the 200 series stainless steel, which was originally developed as a low-cost substitute. This steel uses manganese and nitrogen instead of nickel, so the corrosion resistance is greatly reduced. Its typical composition contains 16% -18% of chromium, but the content of nickel is only 3.5% -5.5%, which is far lower than the standard required for food-grade stainless steel. Although this component makes 201 stainless steel cheaper and easier to process and shape, it also leads to poor corrosion resistance, especially in high acid or high chlorine environment.

Which Grade of Stainless Steel is the Safest for Food and Beverage Contact

Food safety is one of the most difficult areas to compromise in manufacturing. For drinking utensils, the US Food and Drug Administration (FDA), the German Food and Commodity Law (LFGB) and relevant standards of food contact materials in the European Union all require that the product material should be chemically stable even if they are in contact with coffee, juice and sports drinks or in a high temperature environment.

304 and 316 stainless steels can easily meet the above standards. The nickel content of these two alloys is in balance with the alloy proportion, which can provide the required stability and avoid the problems of metal precipitation, discoloration or corrosion. In daily use, these two materials will not change the original flavor of the beverage, nor will they react chemically with the components of the beverage. Even after years of cleaning and use, they can still maintain good sanitary performance.

However, 201 stainless steel cann’t meet the requirements of food grade at all. With the decrease of nickel content, its corrosion resistance decreased. At the same time, the content of manganese is high, which leads to the instability of the material when it comes into contact with acidic beverages or high temperature liquids. It will take a long time for this problem to appear. We have seen some merchants trying to import 201 stainless steel flasks / thermos bottles / metal vessels in order to save costs, but the whole batch of goods was directly rejected by customs. The resulting compliance risk and brand reputation loss are far more serious than its so-called cost savings.

Why Is 316 Stainless Steel A More Expensive Option Than 304?

The cost of 316 stainless steel is mainly determined by its molybdenum content. Molybdenum is an expensive alloying element. Adding molybdenum to steel requires more advanced processing technology and strict quality control. These two points have jointly pushed up the cost of raw materials and the complexity of production technology.

However, this additional cost is not a simple burden, but also a business opportunity. Major brands usually position 316 stainless steel as “medical grade” or “marine grade” material, and such labels can greatly meet the needs and preferences of consumers. High-quality materials naturally adapt to the high-end pricing strategy, and many enterprises have successfully built high-profit product lines around 316 stainless steel products. Although the production cost of 316 stainless steel products will be 20%-40% higher than that of ordinary materials, the increase in its terminal price is often much higher than this ratio. Therefore, it is a strategic choice for brands that focus on high-end markets or performance products.

Explainer Video: Material Guide for Water Bottle Tumbler Cup

How To Determine Which Stainless Steel Is The Right Choice?

The right grade is a function of your market, your product strategy, and your customers’ expectations. For any bottle that will contain beverages, 304 stainless steel should be the baseline: it meets food-safety regulations, balances cost with performance, and satisfies the requirements of most consumers. Brands in demanding environments, coastal regions, outdoor adventure, or health-focused niches, have significant justification for the added cost of 316 stainless steel. It strengthens a product’s story and elevates a brand’s perceived quality.

Which brings us full circle back to 201 stainless steel. While it should never be used for food-contact bottles / double wall vacuum insulated coffee posts / beverage containers / lunch box / custom beer growlers / koozies / shaker bottles, it has its place in the B2B space. For promotional products that do not touch beverages, components hidden within insulated structures, decorative applications, or projects where durability matters more than corrosion resistance, 201 offers a cost-effective option. When positioned correctly and used responsibly, it can lower production costs without compromising consumer safety or product expectations. The key is knowing when its limitations matter, and when they do not.

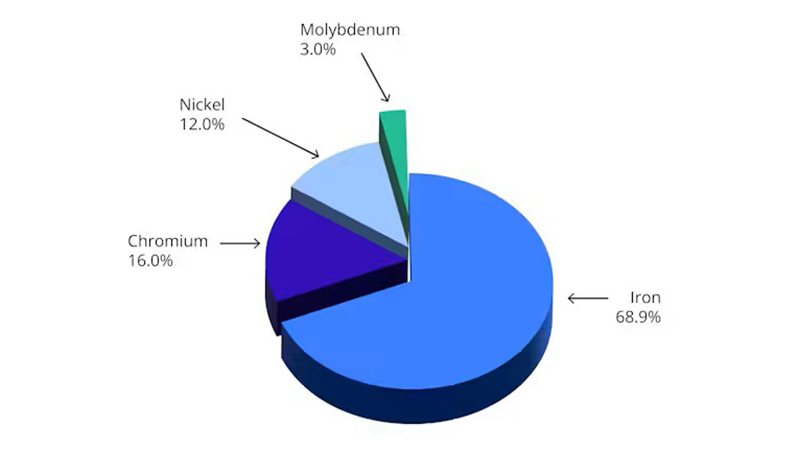

Composition Ratio of SS316

Reliable Ways To Test Or Identify The Grade Of Stainless Steel

In the stainless steel supply chain, material verification is a vital link. The frequency of the appearance of shoddy stainless steel brands, whether intentionally or unintentionally, is far higher than many buyers. Expectations.

X-ray fluorescence spectrum (XRF) analysis is still the most accurate method to identify stainless steel grades, and it can reach the laboratory-level detection accuracy at a near instantaneous speed. The factory is equipped with an X-ray fluorescence spectrum detector, which can detect the incoming materials before production to confirm whether the alloy composition meets the standard. The chemical droplet test is a rapid and low-cost method, which is suitable for on-site detection, but its accuracy is usually not as good as that of X-ray fluorescence spectrometry. The spark test is to judge the general brand category of stainless steel by observing the shape of sparks generated during steel polishing.

After all, the documents itself can never be the only basis for verification. Only by combining third-party independent testing with document verification can you ensure that the products you buy are completely in line with the price paid.

Conclusion

In the field of stainless steel cups, the selection of materials is by no means a simple technical parameter-it is a commitment to safety, reliability and brand reputation.

304 stainless steel is still a balanced, safe and reliable choice for drinking water appliances; 316 stainless steel is a high-end product or a high-performance solution in harsh service environment. As for 201 stainless steel, this material will never be used in food contact cups, but it will be a very good choice in projects with cost control as the primary consideration and corrosion resistance and inflexibility.

Even 201 stainless steel can help to create a scientific and reasonable product layout with clear structure when all kinds of stainless steel brands are used for suitable purposes. The key is to thoroughly understand the performance differences of different materials, recognize the potential risks, and then accurately and definitely match the corresponding materials for the products.

If you need guidance on material selection, manufacturing feasibility, or developing custom stainless steel drinkware, KingStar provides end-to-end support – from engineering insights to full production. Feel free to reach out at sales@waterbottle.tech for project evaluation or technical consultation.