The allure of personalized drinkware is undeniable. From vibrant, unique designs adorning a morning coffee mug to sleek, branded tumblers promoting a business, the demand for custom drinkware continues to surge. If you’re intrigued by starting a customization venture, expanding your existing product line, or simply creating stunning gifts, mastering the tumbler mug heat press machine is your essential first step. This comprehensive guide cuts through the complexity, providing you with the foundational knowledge and practical insights needed to navigate this exciting craft with confidence.

1. What Is a Tumbler Press Machine?

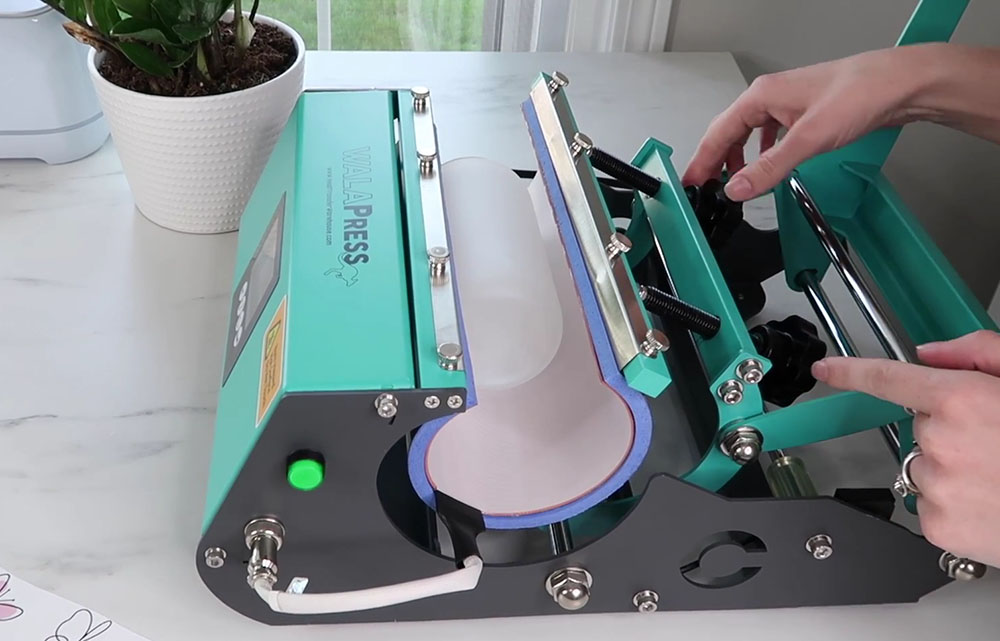

At its heart, a tumbler heat press machine is a specialized piece of equipment engineered to apply precise heat and pressure for transferring designs onto curved surfaces, primarily drinkware. Unlike flat heat presses designed for t-shirts or mousepads, these machines feature unique attachments, typically cylindrical heating elements or flexible sleeves, that conform to the shape of tumblers, mugs, water bottles, jars, and similar items.

The fundamental principle remains rooted in heat press technology: using controlled thermal energy and pressure to create a permanent bond. Sublimation is a process where specially formulated inks, when heated sufficiently, transform from a solid directly into a gas. This gas then permeates the polymer coating on the substrate and solidifies within it as it cools, resulting in vibrant, durable, and scratch-resistant designs that become part of the item itself, not just a layer on top.

2. How to Use a Tumbler Press?

Getting a tumbler press up and running takes just a few straightforward steps. You don’t need a technical background—follow these core stages and you’ll be producing custom drinkware in no time.

- Design & Mirror Printing: Create your design digitally. Crucially, you must print it in reverse (mirror image) onto the sublimation paper using a printer loaded with sublimation ink. This ensures it reads correctly once transferred.

- Preparing the Blank: Ensure your sublimation-ready tumbler or mug is pristine and completely free of dust, oils, or fingerprints.

- Wrapping & Securing: Carefully wrap the printed sublimation paper around the drinkware, ensuring the design is positioned exactly where you want it. Overlap the edges slightly if needed for full coverage, but avoid excessive overlap. Critically, securely fasten the paper using heat-resistant tape. This prevents shifting during pressing and ensures the paper maintains tight, consistent contact with the curved surface. Trim any significant excess paper edges to prevent them from sticking to the heating element.

- Set Your Machine

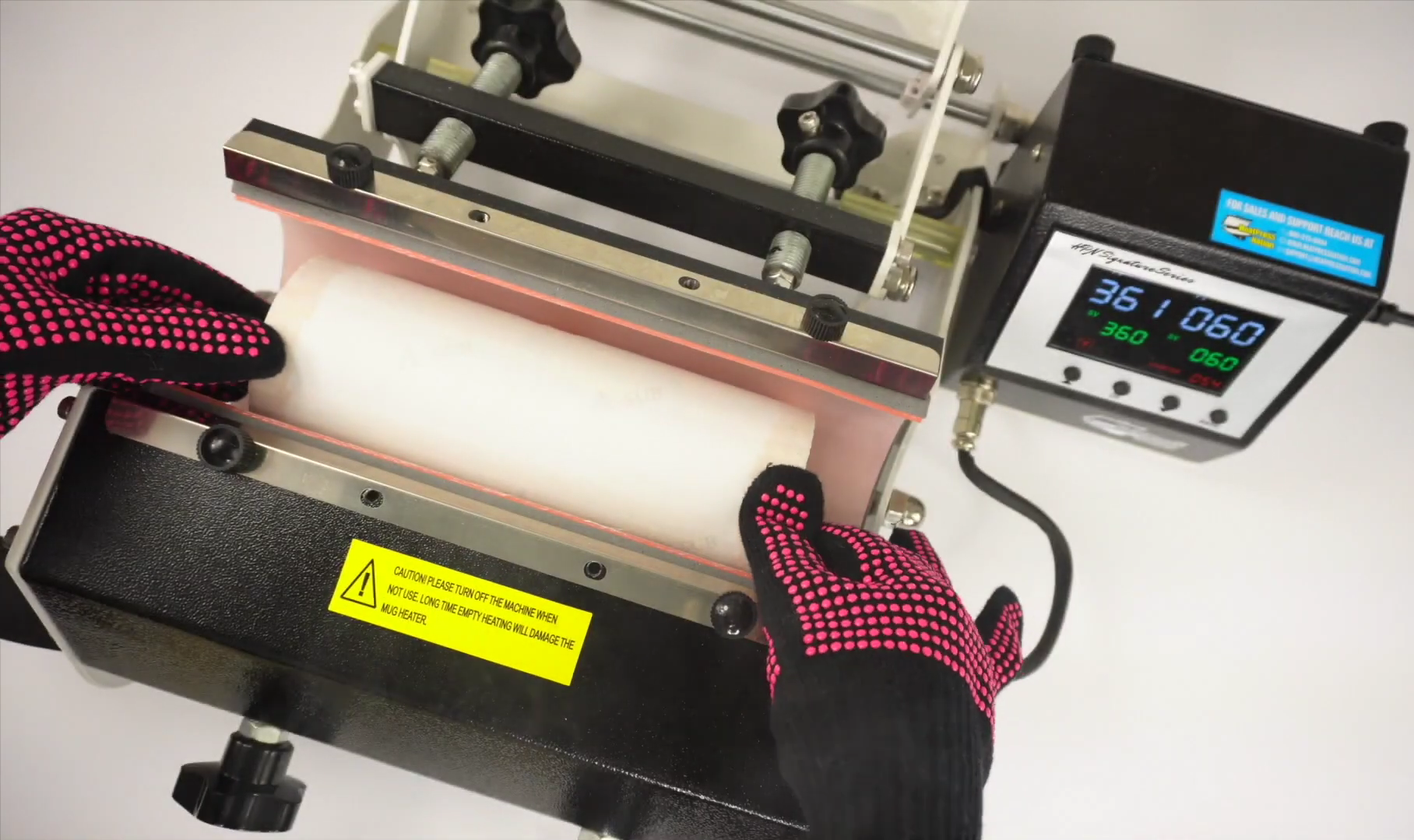

Power on your press and set the temperature—commonly 320°F to 380°F (160°C to 195°C)—and time, usually 20–60 seconds depending on material thickness and ink type. Adjust pressure so the element clamps firmly but doesn’t dent the blank. - Press & Rotate

Insert the tumbler, close the clamp, and start the timer. For full-wrap designs on larger tumblers, you may need to pause halfway, rotate the cup 180°, and press again to achieve edge-to-edge coverage. - Cool & Peel

Remove the hot tumbler with heat-resistant gloves and allow it to cool briefly. Then peel off the transfer carrier to reveal a sharp, vibrant print that’s now part of the blank’s coating.

3. Identifying Your Niche: Where Does Tumbler Pressing Thrive?

Customized drinkware isn’t just a novelty; it’s a versatile product that appeals across demographics and industries:

- Personalized Gifts: Birthdays, weddings, anniversaries, holidays —you name it. Adding a name, date, or heartfelt message instantly turns a functional item into a keepsake.

- Corporate Branding: Logoed tumblers and mugs are perfect for employee appreciation, trade show giveaways, or client gifts. They keep your brand top of mind with every sip.

- Team & Club Merchandise: Schools, sports teams, charities, and hobbyist groups love tumblers emblazoned with team colors or mascots—great for fundraising or team spirit.

- Retail & E-commerce: Cafés, boutique shops, and online stores often sell drinkware as part of their merchandise line, offering limited-edition or seasonal designs.

- Event Souvenirs: Conferences, festivals, and special events turn custom tumblers into memorable swag that attendees actually use, extending your marketing beyond the venue.

4. Key Features and Functions: What to Look for in a Tumbler Press

Modern tumbler presses offer features beyond basic heating. Understanding these helps select the right machine for your needs, especially for business:

- Multiple Stations: Crucial for high-volume production. Machines with 2, 3, or even 4 independent pressing stations allow simultaneous processing of multiple items, dramatically boosting output. Each station typically has independent temperature and timer controls.

- Extended Heating Elements: An alternative to multiple stations for medium volume. A single, extra-long heating sleeve allows pressing two (or sometimes more) shorter tumblers end-to-end in one cycle, or covering more of a taller item with fewer rotations.

- Adjustable Pressure Mechanisms: Consistent and adequate pressure is vital. Look for machines with reliable, easy-to-adjust mechanisms (knobs, levers, pneumatic systems) to ensure even contact across the curved surface for different blank thicknesses.

- Precise Temperature & Time Controls: Digital PID controllers offer superior accuracy and stability compared to analog dials. Consistent, reliable temperature is non-negotiable for quality sublimation. Easy-to-set digital timers are essential.

- Safety Features: Thermal cutoff switches, insulated handles, clear safety instructions, and stable bases are important considerations.

- Compatibility & Adaptability: Consider the range of blank diameters and lengths the machine’s heating element(s) can accommodate. Does it require separate sleeves for different sizes? Can it handle tapered tumblers effectively?

- Ease of Use & Workflow: Consider the machine’s footprint, weight, ease of loading/unloading, and how it integrates into your workspace. Swing-away or sliding mechanisms can be ergonomic advantages.

5. Pro Tips for Flawless Results

Test First: Never blindly follow generic settings. Always perform test presses. Variables include your specific press model, blank coating, sublimation paper, ink batch, and even ambient humidity. Test on spare blanks or inconspicuous areas to dial in the perfect time, temperature, and pressure combination before committing to a large batch. Document your successful settings for each blank type.

Invest in Quality Consistently: This applies across the board:

- Press: A well-built, reliable machine with accurate controls is foundational.

- Blanks: High-quality sublimation blanks with consistent, durable coatings are non-negotiable for vibrant, lasting results. Cheap blanks often equal poor transfers and frustrated customers.

- Ink & Paper: Use reputable sublimation inks and paper designed to work together. Cheap alternatives lead to color shifts, poor ink release, and ghosting.

- Tape: Genuine heat-resistant tape is essential to prevent paper slippage and withstand the heat without leaving residue.

Meticulous Preparation:

- Surface Perfection: Any contamination (dust, oil, moisture) on the blank is the enemy of adhesion. Clean thoroughly with isopropyl alcohol and lint-free cloths immediately before pressing. Handle blanks by the rim or base after cleaning.

- Design Precision: Ensure designs are mirrored correctly before printing. Trim sublimation paper edges cleanly to avoid white lines transferring. Position the design meticulously on the blank before taping.

- Tight, Secure Wrap: The sublimation paper must be in intimate contact with the blank’s surface over the entire design area. Wrap tightly and secure thoroughly with heat tape, especially at the edges and overlap points. Any gap causes blurring or incomplete transfer.

Mastering Pressure & Heat:

- Even Pressure: Ensure the pressure mechanism is adjusted correctly so pressure is uniform along the entire length of the heating element contacting the blank. Uneven pressure leads to patchy transfers.

- Consistent Temperature: Allow ample preheat time for the element to reach and stabilize at the target temperature. Avoid opening the press unnecessarily during preheating. Ensure good contact between the heater and the blank.

- Patience During Cooling: Resist the urge to peel the paper while the blank is hot. Let it cool completely to room temperature. Premature removal can cause the ink to smear or not fully bond.

Safety First, Always:

- Heat-Resistant Gloves: Essential for handling hot blanks and heating elements. Burns are a real risk.

- Workspace: Operate in a well-ventilated area. The sublimation process releases minimal but present fumes. Keep the machine stable on a heat-resistant surface away from flammable materials.

- Machine Awareness: Be mindful of moving parts and hot surfaces. Keep loose clothing and hair secured.

6. Choosing the Right Tumbler Press for Your Business

Your ideal machine depends on:

- Order Volume: Single-station presses are fine for ≤50 items/week. Multi-station or long-heat presses suit 100+ items.

- Blank Variety: What sizes (diameter and height) and types (straight, tapered) of drinkware will you primarily work with? Ensure machine compatibility.

- Space Constraints: Measure your available workspace. Tumbler presses, especially multi-station ones, need dedicated space.

- Budget: Set a realistic budget, considering not just the press, but also blanks, ink, paper, tape, and a printer if needed. Remember, quality equipment is an investment.

- Growth Plans: If you plan to scale quickly, invest in expandability—interchangeable heaters or dual-station units.

For beginners and small-batch makers, a tumbler press is a fast, intuitive way to kickstart your custom drinkware business. As your orders grow or you branch into varied shapes—skinny tumblers, wide-mouth mugs, novelty jars—a sublimation oven or dual-station press can boost capacity and versatility.

No matter which path you choose, success depends on mastering preparation, precise settings, and quality blanks. Speaking of blanks, KingStar proudly offers wholesale custom stainless steel blank tumblers and mugs with full OEM & ODM support, helping wholesalers, suppliers, and retailers bring vibrant, durable drinkware to market with ease. Feel free to send us a message online or email us at sales@waterbottle.tech, and you’ll receive a response within 24 hours.