Contents

- Is the Vacuum Insulated Cup You Use Daily Safe?

- The Odor Emitted From Your New Stainless Steel Cup/Vacuum Insulate Bottle is a Dangerous Sign

- Choose the Qualified Thermos Metal Cups and Lead a Healthy Lifestyle

- What Type of Vacuum Insulated Cups Should We Buy and How to Use it Safely?

- What Should Stainless Steel Cups Manufacturers Do?

Is the Vacuum Insulated Cup You Use Daily Safe?

“Globally, more than 80% of diseases and 33% of deaths are related to polluted water.” noted in an article released by the China water magazine. The environment can exert an impact on water quality, which may lead to pollution. However, it is more likely that the problem lies in the drinkware we use.

The Odor Emitted From Your New Stainless Steel Cup/Vacuum Insulate Bottle is a Dangerous Sign

The peculiar smell is often the combination of the strong acid and the heavy-metal polishing technique used on the inner wall of the vacuum cups and improper cleaning. Therefore, there will be some acid and heavy metal materials left on the surface of the cup, which will make their way into human bodies and exert hazardous impact on people’s health.

19 of the 50 different types of thermal insulated cups KingStar has randomly bought from the supermarket, mall and online shop show serious problems such as excessive heavy-metal residues. During the testing, vacuum cups using electrolytic polishing technique have shown significant corrosion on the inside wall of the vacuum cups.

Choose the Qualified Thermos Metal Cups and Lead a Healthy Lifestyle

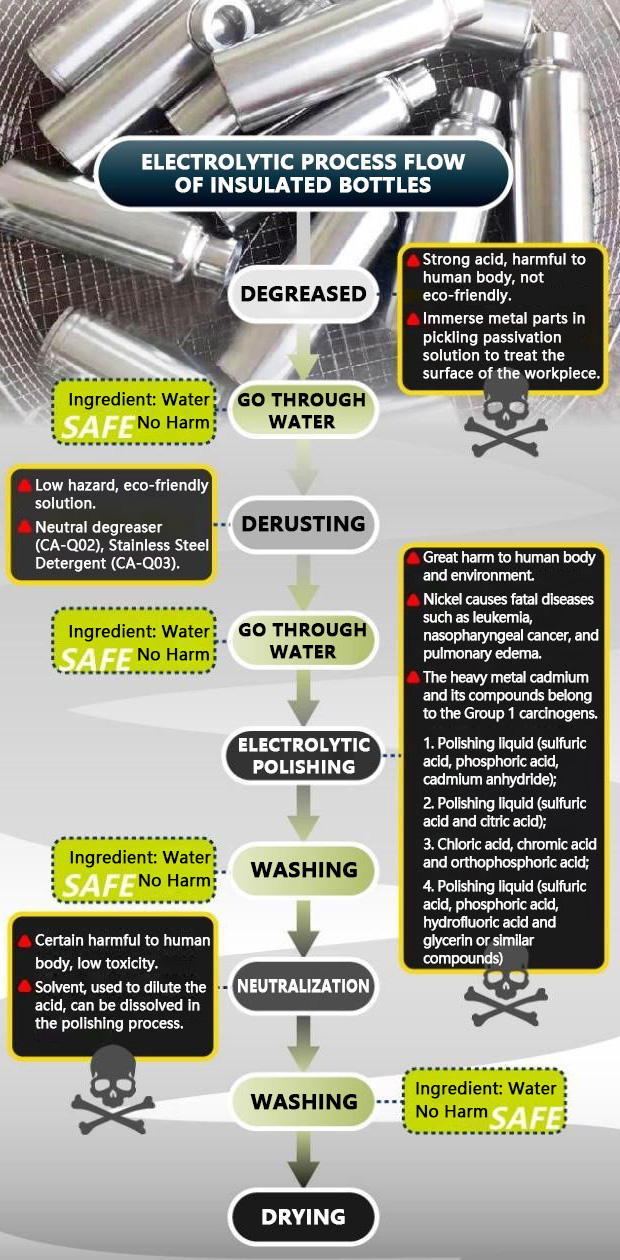

The most widely used techniques for the manufacturing of vacuum cups are electrolytic polishing, chemical polishing and electric plating. Some techniques will require heavy metals such as chrome, nickel, gold and silver. The electrolytic polishing solution is quite noxious and can pose a threat to people’s health. Except the main chemical materials such as sulfuric acid, phosphoric acid and chromic acid, some poisonous heavy metals such as hexavalent chromium and nickel that are regarded as carcinogens by the WHO can also be found.

Using vacuum cups containing excessive heavy metal for a long time can cause symptoms such as dizziness, nausea, vomiting and insomnia. Besides, it can seriously damage your liver, kidney and even leads to cancer. For children who often use this cup, it will lead to a decline in immunity, loss of appetite as well as more serious conditions like stunting, mental decline and other situations.

What Type of Vacuum Insulated Cups Should We Buy and How to Use it Safely?

Check: check the production information carefully before purchasing, and see if there are residues left on the inner wall of the cup as well as the rim of the cup. Make sure that the rim of vacuum cup is smooth and avoid to buy the cup that is poorly made.

Smell: after buying your vacuum cup, check if there is weird odor inside the cup. You can put some water into the cup and wait for 24 or 48 hours and see if you can smell anything.

Ask: there are some information you should know before purchasing: the materials, manufacturing process, whether the electrolytic polishing is used and is it environmentally friendly.

We are now experiencing a global pandemic, which helps us realize the importance of a healthy body and health security. The ongoing pandemic and the rising threat of diseases such as coronary heart disease, cerebral apoplexy and high blood pressure pose the question: how can the viruses and diseases still be so rampant in the today’s world where we enjoy a relatively high-level livelihood and advanced health care system? The key factor is water. The priority of the UN and the Bill & Melinda Gates Foundation is to solve water problem. We should pay more attention to the safety of water supply and preventing the secondary pollution of drinkware.

What Should Stainless Steel Cup Manufacturers Do?

A responsible stainless steel cup manufacturer should thoroughly clean the cup after employing electrolytic polishing technique, and then test the pH level of the surface of stainless steel cups. Only when the pH level is higher than 6.5 can the semifinished cups be transferred to the next manufacturing procedure.

Kingstar has always been strict with its cleaning process and make sure that every stainless steel cup it produces is thoroughly cleaned without any acid residues left on its surface before delivering them to other countries.