Custom drinkware is booming—whether it’s personalized tumblers for brand promotions or custom mugs for online shops, the demand is only going up. For small businesses, wholesalers, or retailers looking to get into or scale up sublimation printing, one of the biggest decisions comes down to choosing the right equipment. Both tools can produce high-quality results—but they work differently, and choosing the right one depends on your business needs.

In this guide, we’ll compare how each machine works, highlight their pros and cons, and help you decide which is better suited for your custom drinkware production—whether you’re just starting out or scaling up.

1. What Is a Sublimation Oven?

A sublimation oven is a specialized heating device used to apply printed designs onto curved or irregularly shaped items—like tumblers, mugs, and water bottles. It works by providing a consistent, high-temperature environment that allows sublimation ink to turn into gas and bond with the coated surface of a blank.

Unlike single-item tumbler presses, sublimation ovens are designed for batch processing. This type of oven has become increasingly popular among small to mid-sized printing businesses due to its versatility.

2. How Sublimation Ovens Work for Tumbler and Mug Printing

Sublimation ovens rely on a process that combines time, temperature, and pressure—though in this case, the pressure comes from external wraps rather than a built-in clamp, like in a mug press.

Here’s a general idea of how the process works when printing on tumblers or mugs using a sublimation oven:

- Design and Print: First, you create a design using graphic design software and print it using a sublimation printer with special sublimation ink. Always remember to mirror the design before printing.

- Prep the Blank: Wipe the blank tumbler or mug with a lint-free cloth and alcohol to remove dust, oil, or fingerprints. This ensures better ink transfer.

- Wrap the Design: Align the printed sublimation paper onto the blank surface and secure it tightly using heat-resistant tape. Then, cover the entire item with either shrink wrap or a silicone sleeve. A heat gun is used to shrink the wrap evenly around the item.

- Bake in the Oven: Preheat your sublimation oven to the recommended temperature—typically between 360°F and 400°F. Once it reaches the target heat, place your wrapped blanks inside. It’s important they don’t touch each other or the oven walls to ensure even results.

- Cool and Unwrap: After the time is up, use heat-resistant gloves to carefully remove the hot items from the oven. Let them cool slightly, then peel off the wrap and sublimation paper to reveal your transferred design.

3. Pros and Cons of Sublimation Ovens

Sublimation ovens have become a top choice for many custom tumbler and mug businesses—especially those handling bulk orders or diverse drinkware shapes. However, like any equipment, they come with both advantages and limitations. Let’s break them down clearly:

Pros:

- Batch Production Made Easy: You can sublimate multiple tumblers or mugs at once, saving time on larger orders. Perfect for growing businesses or peak seasons.

- Wrap-Around Printing: Because the heat surrounds the item evenly, full-wrap designs turn out smoother and more consistent, with fewer faded edges or pressure spots.

- Versatility with Shapes: Sublimation ovens accommodate a wide range of products—tumblers, mugs, bottles, even plates—making them ideal for businesses offering multiple drinkware options.

- Fewer Manual Steps Mid-Process: No need to rotate mugs mid-print like with some presses. Once loaded, the oven does all the work.

Cons:

- Longer Prep Time: Each item must be taped, wrapped, and sometimes shrunk with a heat gun before going into the oven, which adds time upfront.

- Not Ideal for One-Off Prints: If you’re only printing a single mug or small batch, it’s less time-efficient than using a mug press.

- Takes Practice to Perfect: Mastering the right time, temperature, and wrap technique for different blanks can take a few trial runs.

- Additional Supplies Required: Shrink wrap or silicone wraps and a heat gun are all needed to use the oven effectively, which adds to setup cost.

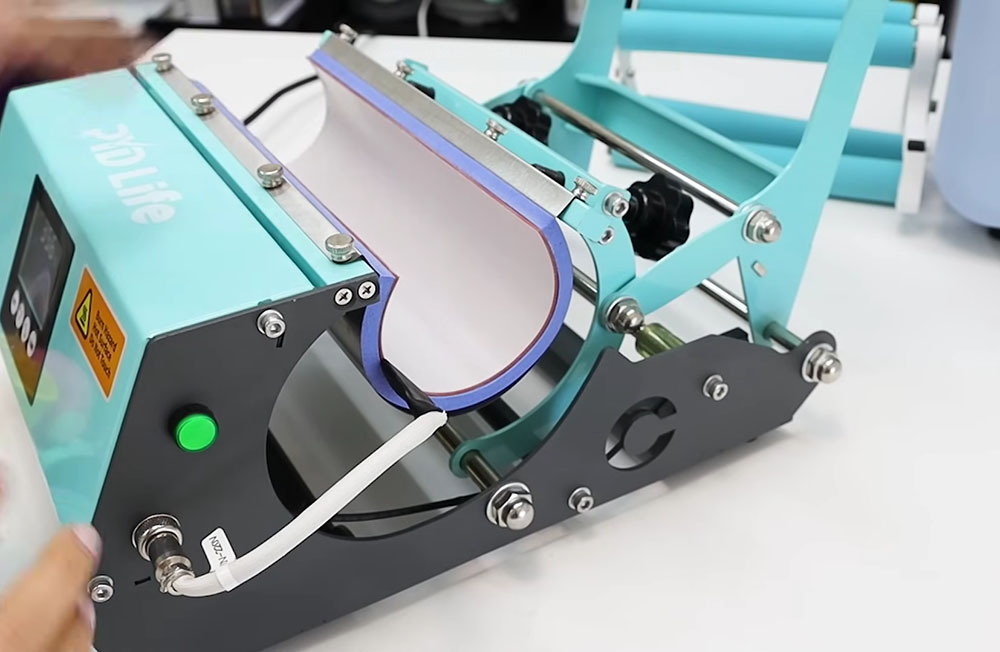

4. What Is a Tumbler Press?

A tumbler press is a compact heat press machine designed specifically to transfer sublimation prints onto drinkware such as mugs, tumblers, and bottles. Most mug presses use a clamshell or wrap-around heating element that clamps down onto the item, holding it firmly in place while heat and pressure drive the sublimation ink into the coating. They’re typically digital, allowing users to set precise time and temperature for optimal results.

What’s more, many tumbler presses accommodate different sizes—like 11 oz mugs, 20 oz skinny tumblers, or even 30 oz water bottles—making them flexible tools for startups, hobbyists, or small-batch customizers.

5. How a Tumbler Press Works for Tumbler Mug Printing

Using a tumbler press is straightforward, which makes it a favorite among beginners and small business owners. Here’s a simple overview of how it works:

- Prepare the Design: First, create your design using graphic software. Be sure to mirror the image before printing it on sublimation transfer paper.

- Wrap the Tumbler or Mug: After printing, carefully align and wrap the sublimation paper around the tumbler or mug. Secure it tightly with heat-resistant tape to avoid any shifting during the process.

- Set the Press: Preheat the tumbler press according to the temperature and time recommended for the material you’re working with—typically around 350°F to 400°F for 45 to 60 seconds, depending on the substrate and design.

- Insert and Press: Place the wrapped drinkware into the press and close the clamp. The press applies firm, even pressure while heating the surface, allowing the sublimation ink to bond with the tumbler’s coating.

- Rotate if Necessary: For larger tumblers or full-wrap designs, you might need to rotate the item halfway through the press cycle to ensure even coverage on all sides.

- Cool and Unwrap: Once the time is up, use heat-resistant gloves to remove the tumbler. Let it cool slightly, then peel off the tape and paper to reveal your custom print.

Click and read more about custom tumbler mug printing: How to Make Heat Press Sublimation Tumblers & Mugs, Best Heat Press Machine for Small Custom Printing Tumbler Mug Business

6. Pros and Cons of Tumbler Press

A tumbler press also comes with both advantages and limitations. Understanding these can help you decide whether it fits your workflow and business goals.

Pros:

- Beginner-Friendly: Tumbler presses are simple to set up and use. Most models are plug-and-play with straightforward temperature and time settings.

- Quick Turnaround: Ideal for producing small batches or personalized items quickly. Pressing a single mug or tumbler usually takes under a minute.

- Compact Design: Doesn’t take up much space. Perfect for home-based businesses, workshops with limited room, or mobile setups at craft fairs.

- Precision: Applies direct heat and pressure, leading to vibrant, consistent prints—especially for straight-sided drinkware.

- Budget-Friendly: Generally more affordable than sublimation ovens, making it an attractive choice for startups or those testing the market.

Cons:

- Limited Capacity: Only one item can be pressed at a time. This becomes a bottleneck during high-volume production.

- Shape Restrictions: Most presses work best with straight-sided drinkware. Curved or oddly shaped items may not sublimate evenly.

- Manual Labor: Requires hands-on attention. You’ll need to monitor each pressing cycle and often rotate items manually for full coverage.

- Not Ideal for Scaling: As orders grow, a single tumbler press may struggle to keep up with demand compared to batch-processing ovens.

7. Side-by-Side Comparison: Sublimation Oven vs. Tumbler Press

Below is a clear, side-by-side comparison to help you quickly assess which might better suit your business needs.

Feature |

Sublimation Oven |

Tumbler Press |

|---|---|---|

| Capacity | Can sublimate multiple items at once (bulk friendly) | Typically handles one item at a time |

| Supported Shapes | Works with curved, irregular, and straight items | Best for straight-sided mugs or tumblers |

| Setup Time | Longer setup with shrink wrap or silicone sleeves | Quicker prep and press process |

| Learning Curve | Moderate — requires experimentation | Low — beginner-friendly and easy to master |

| Space Requirements | Takes up more space in a workshop | Compact and great for small work areas |

| Production Volume | Ideal for high-volume printing | Best for small-batch or one-off customization |

| Print Quality | Excellent, with uniform results | Also excellent, especially for standard mug shapes |

| Speed (per item) | Slower per item but faster in bulk | Fast per item but slower for large orders |

| Cost Efficiency | More cost-effective for large-scale production | Affordable entry-level option for smaller businesses |

Summary:

- Choose a sublimation oven if you’re planning to scale up production or work with a variety of tumbler shapes and sizes.

- Go with a tumbler press if you need a simple, fast, and space-saving solution for custom mugs or tumblers in small batches.

8. How to Choose Based on Your Business Needs

Choosing between a sublimation oven and a tumbler press should be based on your specific goals, order volume, and flexibility needs.

If You’re Just Starting Out

- Best choice: Tumbler Press

A tumbler press is compact, simple to operate, and budget-friendly. It’s perfect for individuals or small businesses looking to create personalized mugs or tumblers without a steep learning curve. You can get started quickly and build your skills without investing in extra tools like shrink wraps or silicone wraps.

If You’re Scaling Up Production

- Best choice: Sublimation Oven

For businesses handling bulk orders or offering a wide variety of drinkware shapes and sizes, a sublimation oven offers better long-term value. It can process multiple items at once and works well with irregularly shaped products—saving time and opening doors to more customization options.

If You Need Flexibility in Product Range

- Best choice: Sublimation Oven

The oven is ideal if you plan to expand into items like flasks, bottles, or even ceramic plates. Its versatility makes it a smart investment for businesses looking to diversify.

If Speed and Simplicity Matter Most

- Best choice: Tumbler Press

A heat press allows you to work quickly and consistently with minimal prep. It’s especially effective for standard-sized mugs and tumblers where quick turnaround is important—such as for personalized gifts or event merchandise.

If You’re Short on Space

- Best choice: Tumbler Press

These machines are more compact and can easily fit on a desktop. If you’re operating from a home studio or have limited space, a tumbler press is the more practical option.

At the end of the day, the choice between a sublimation oven and a tumbler press depends on what your business values most—versatility, speed, cost, or production scale. While both machines can deliver stunning results, they serve different needs. Assess your business goals, expected order volume, and available space before committing to one. If you anticipate growth or want to diversify your offerings, investing in both might be a smart long-term strategy.

And when you’re ready to scale with quality materials, KingStar offers a wide range of premium stainless steel blank tumblers, mugs, and bottles—perfect for any sublimation setup, with full OEM & ODM support. For more information, feel free to contact us online or via email to sales@waterbottle.tech.