What is polishing? Polishing is the work to make the surface of stainless steel water bottles smooth and shiny by rubbing or chemical actions. There are four ways for polishing: mechanical polishing, sandblasting, chemical polishing and electropolishing. This article details electropolishing in the following part.

Electropolishing is a polishing process of putting a stainless steel water bottle into an electrolyte solution to create a shiny, smooth, ultra-clean surface for the bottle.

In electropolishing, a stainless steel water bottle / jug / cup / tumbler / bowl / growler / thermos / flask / food container / vessel / metal drinkware serves as the positively-charged anode and insoluble metal as the negatively-charged cathode, both of which are immersed in a electrolyzer simultaneously. The ionization reaction produced in the electrolyte solution will dissolve extremely small, tightly controlled amounts of the anode, so as to remove surface defects and improve surface luster of a stainless steel water bottle.

Polishing principle of electropolishing technology

The metal ions dissolved from the stainless steel water bottle reacts with the phosphoric acid in the polishing liquid, forming a phosphate film attached on the surface of the inner wall of the stainless steel water bottle. This film is thin in the convex and thick in the concave place, due to the fact that high current density of the convex results its fast dissolution. With the coating flow, the coating thickness in the concave and convex continues to change, which is a gradual process of smoothing the rough surface.

The stainless steel water bottle is used as the anode connected to the DC power supply, with the conductive materials like lead and stainless steel which are resistant to electrolyte corrosion as the cathode. Then both electrodes are immersed in the electrolyte (generally composed with sulfuric acid and phosphoric acid) at a certain distance. With certain temperature, voltage, current density (generally less than 1 A / square centimeter) and a certain period of power-on (generally tens of seconds to minutes), the tiny protruding parts on the surface of the stainless steel water bottle will be the first to be dissolved, resulting a smooth and lustrous surface.

Specific electropolishing process of a stainless steel drinkware

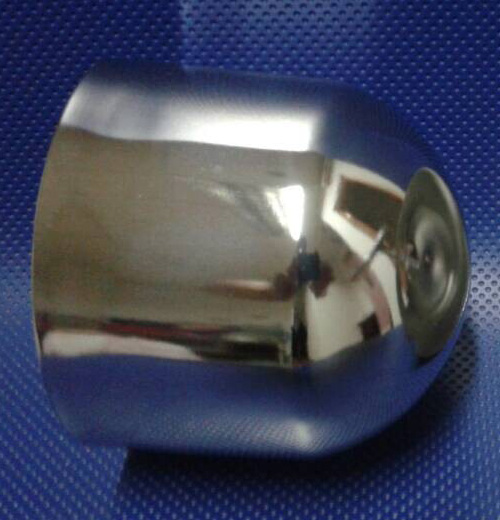

At the beginning, let’s look at samples which hasn’t been processed from our customers. (The sample is the bottle cup made of 304 stainless steel.)

Tip 1: After a series of operation, oil stains still remain on the surface of bottle cup. So oil removal is a key step before electrolytic polishing, which begins after these stains disappear.

Tip 2: Heat the polishing liquid to 55~60 degrees, adjust the voltage to about 7~9 volts and wait for about 2 minutes, then we can take out the stainless steel water bottles from the solution. (Due to the small number of stainless steel water bottles, the electrolysis time is relatively shorter)

Figure 2 is a picture where a worker is electropolishing the stainless steel bottle cup.

Click and read more about Custom Options: Custom Bottle Tumbler Decorating, Custom Logos of Water Bottles, Custom Water bottle Packaging

KingStar is a leading stainless steel bottle cup manufacturer in China. We provide one-stop custom water bottle manufacturing service from design concept, prototype generation, mass production to global shipping.