The electrolytic polishing technique used in manufacturing stainless steel cups is employed on the inside of a stainless steel cup to make it smooth and sheen. During the process, the stainless steel cup to be polished is an anode and the insoluble metal acts as a cathode, and put them into the electrolysing cell. Then the direct current will help produce the selective anodic dissolution, which will make the surface of the stainless steel cup become smooth and then help add more luster to the surface of the stainless steel cups ( vacuum flasks, insulated water bottles, stainless steel tumblers, metal cups, double wall mugs etc).

Theory

It is widely believed that the theory of the electrolytic polishing of stainless steel derives from the chemical membrane theory.

How does the theory work: the metal ion separated from the workpiece and the phosphoric acid from the polishing fluid will form a layer of phosphate film that will attach to the surface of the workpiece. The phosphate film is thinner in the raised parts and thicker in the concave parts, because the raised parts have higher current density and therefore dissolve quickly. With the flow of the film, the raised and concave parts will be in constant flux and the rough surface will eventually become smooth.

Advantages

- The sheen of the inside of the stainless steel cup will be even and last for a long time. Even the concave parts that may not be reached by the mechanic polishing can be smoothed out.

- It helps improve the production efficiency and reduce costs.

- It Increases the corrosion resistance of the inside of the stainless steel cups. The technique can be applied to all types of stainless steel cups such as the SS 316, SS 304 (18/8 stainless).

The process requirements

The electrolytic polishing technique used for stainless steel cups does not have a strict requirement for the power waveform, so it can also use silicon control or high frequency.

The open circuit voltage: 0-20V.

The operating voltage should be under 6V; the polishing speed is slow and there is not enough light.

The electrolysing cell and infrastructure(anode stub) can welded by polyvinyl chloride hard sheets. Then install three electrode bars in the electrolysing cell and the middle one should be the moveable anode stub connecting to the anode (or the positive electrode) of the power. The cathode bar should be put on both sides connecting to the positive electrode(or cathode).

Heating and cooling facility:

- Both the quartz heating tube and the titanium heating tube can be applied to the heating process.

- The coiled pipe can be used for cooling, and it can also be applied for heating.

clamping fixture:

The most ideal racks are made of titanium because this metal is corrosion proof, enjoys a longer lifespan and titanium ions exert no effect on the bath solution. It is recommendable to avoid racks made of copper because this metal will form a layer of copper that lacks cohesion on the surface of the stainless steel after copper ions reach the surface, which will have a negative effect on the polishing quality. The PVC glue can be used to help form a film on the exposed parts of the copper surface, and then scrape off the dielectric film at the contact point.

The materials used for the cathode and the anode:

The cathode and anode bars should be copper bar or copper tube. The copper tube should be more than 20 centimeters longer than the length of the electrolysing cell and the cathode plate should be lead. The lead plate should be fixed onto the cathode bar and has a length 10 centimeters longer than the height of the electrolysing cell. The width of the lead plate should depend on how long the electrolysing cell is, and typically it is 10 centimeters or 20 centimeters.

The polishing technique used for stainless steel cups is mainly employed on the inside of the cup to make it smooth and sheen. The stainless steel cups can also be classified as 304 stainless steel and 306 stainless steel, and different electrolytic polishing solutions should be used for different types of stainless steel materials.

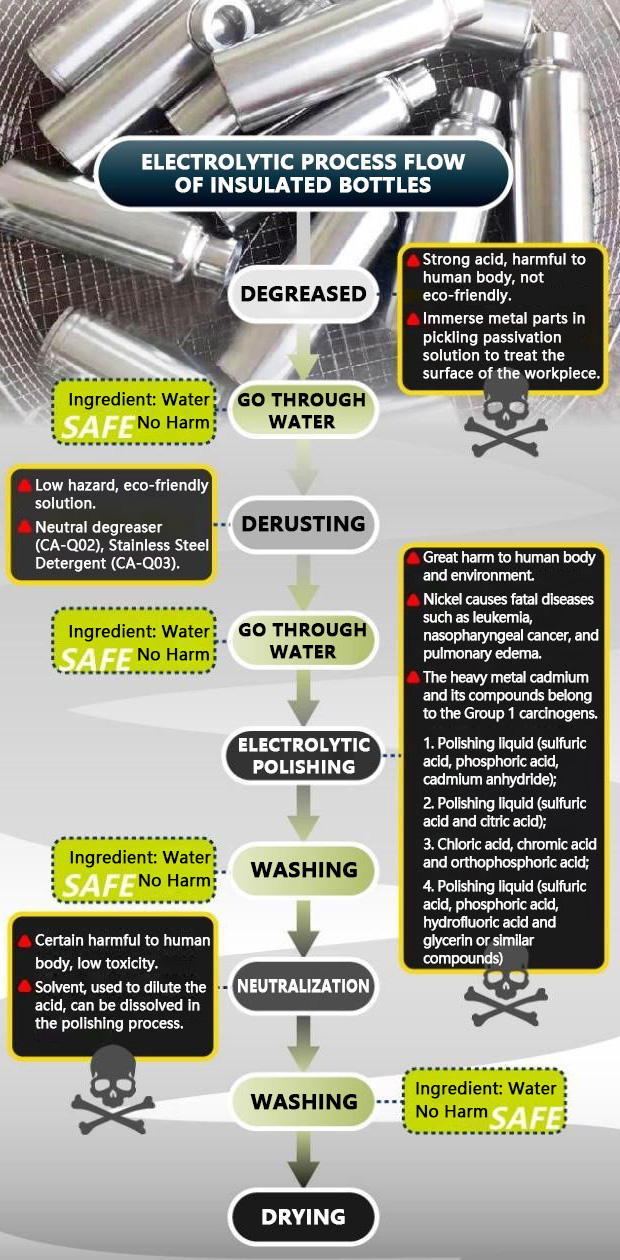

The process of the electrolytic polishing technique: degreasing–rinsing–descaling–rinsing–electrolytic polishing–rinsing—neutralization–rinsing–deactivation–packaging.

Click and read more about stainless steel tumbler cup manufacturing technology: Metal Cup Manufacturing Process

Electrolytic Polished Stainless Steel Mug

The latest equipment & facility

With the increasing development of the electrolysis technology, the demand for the electrolytic polishing facility is even higher during the electrolytic polishing process. The current electrolytic polishing facilities mainly consist of the electrolysing cell, washing tank, chromate and anti-finger coater and the descaling bath. The components include the copper tube, lead plate and electrolytic solution. Among them, the electrolysing cell, washing tank, chromate and anti-finger coater and the descaling bath must be wielded by the high-end PPG plate in order to help them withstand high temperatures and corrosion as well as making them ametabolic. The effect of the electrolysis will be better with the special electrolytic facility.

The prospect of the electrolytic polishing technique used for stainless steel cups

There are not many stainless steel cup manufacturers that can independently operate the electrolytic polishing technique, not to mention how few manufacturers that have their own core intellectual property rights and manufacture excellent products.

Many stainless steel drinkware manufacturers do not have their own electrolytic polishing workshop so many of them just outsource it, which lead to the poor electrolytic quality of the cups.

KingStar is remaining committed to improving its electrolytic polishing technique and will further lower the process costs and decrease the pricing of bulk stainless steel cups.