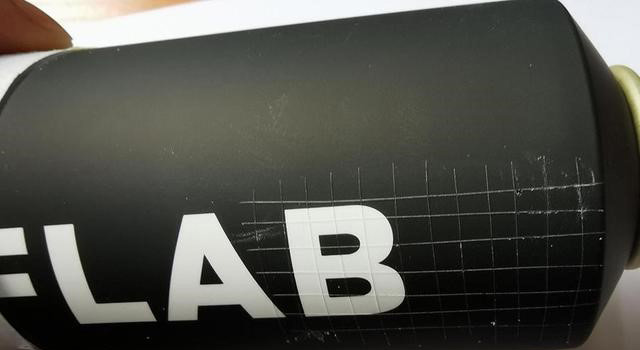

Rubber paint is also known as leather paint and fleece paint. Sprayed on the surface of the wholesale metal cups, it is in a matte or semi-matte state, the hand feels quite delicate and smooth, and the appearance is elegant and solemn. Excellent scratch resistance, weather resistance and abrasion resistance. In line with environmental protection printing, without any damage to the human body.

The advantage of rubber paint

Rubber paint is widely used in ABS, PVC, PC, PS, and other plastic products, as well as hardware, metal, bakelite, wood, ceramics and other products sprayed with special primers.

The products sprayed with rubber paint have a special soft, smooth, delicate, sensual touch and a rubber-like texture like the skin, giving people a very pleasant feeling, comfortable and pleasant.

The quality issue of spraying rubber paint on the metal cup surface

The metal water cup has a good touch feel and other decorative properties through the process of spraying rubber paint on the surface, which is very popular among consumers.

However, there are two problems with spraying rubber paint on the surface of metal water cups (stainless steel water cups), one is that the yield is very low, and the rubber paint is easy to fall off;

It is difficult for the rubber paint to adhere to the bottle, which has become a problem faced by the water cup manufacturing industry. How to enhance the adhesion between the metal water cup and the rubber paint has become an important breakthrough in solving the problem of paint peeling. Let’s take a look at how KingStar solves the problem of metal water cup spray rubber paint falling off.

Problem phenomenon

After spraying rubber paint on the surface of the metal water cup, the coating is tested for adhesion, the paint is peeled off in the 100 grid test, and the peeling defect is found in the friction test.

Solution

- KingStar completely clears the oil, dust, etc. attached to the surface of the metal water cup.

- Among the important factors affecting the adhesion, the weak interlayer bonding force between the metal water cup and the rubber paint is also an important factor that makes the rubber paint difficult to adhere. KingStar’s solution is to first spray a special primer to improve the adhesion properties of the metal surface, and at the same time enhance the mutual bonding with the rubber paint to form a strong special primer layer on the metal surface.

Process steps

- Clean the surface of the stainless steel bottle

- Spray KingStar’s special primer and bake at 70℃ for 3-5 minutes

- Spray rubber paint

- Carry out the required relevant adhesion tests, etc.

Have questions regarding rubber painting water bottle tumblers? As the top stainless steel tumbler cup manufacturer, KingStar is here to help you.