$25.17-29.45

Product Features:

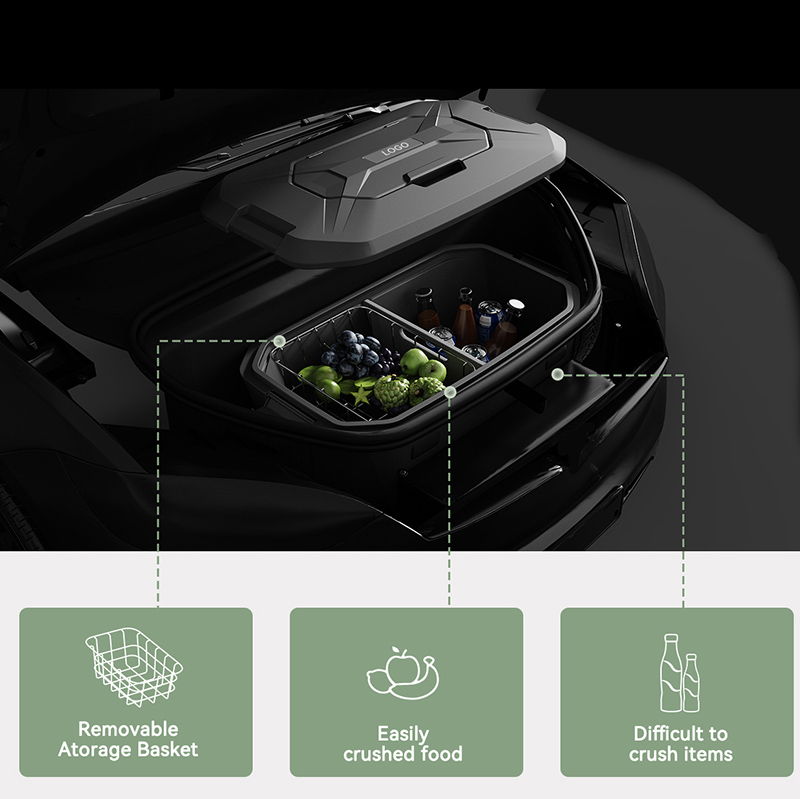

- Dual-opening option and intelligent storage design: It features two convenient lid-opening methods – the full lid opening is suitable for arranging and storing items before setting out, while the small flip lid opening is for taking out or storing individual items during use (to reduce the exchange of cold and hot air and extend the cold preservation time). It is equipped with a dual-side buckle and a detachable storage basket (covering half of the internal area), which can separate fragile and non-fragile foods for storage, optimizing space utilization.

- 48-hour cold preservation: It uses high-performance insulation materials, available to preserve ice for 48 hours or more. The inner insulation layer supports customization of PU, EPS or other materials, and is equipped with a silicone sealing ring to enhance leak-proof performance.

- Durable and easy-to-clean construction: The box body is made of high-quality PP material, with a waterproof surface, stain-resistant, and easy to clean. All materials including inner&outer walls are BPA-free and food grade, safe for direct food contact. The embedded bag lid design provides additional protection, suitable for long-term outdoor use and frequent transportation.

- Customizable and multi-scenario applicability: Supports custom brand logo printing and various color combinations (blue + gray, blue + black, black + gray, or other custom colors). Perfectly fits the front trunk, maximizing space utilization, and is an ideal choice for camping, fishing, parties, and other outdoor activities.

Customizing Options:

- Materials: The box body can be made of PP or PE (LLDPE, HDPE); the insulation layer can be made of PU or EPS; the accessories can be customized in any material solely or combined – thermoplastic elastomer, rubber, 304/316 stainless steel, nylon. Or other materials you specify or provide.

- Molding Technique: Rotomolding, injection molding, blow molding.

- Capacities & Shape: Please communicate with our engineers. Might be necessary to build a mold from scratch.

- Logo, Text, Pattern: Screen printing, heat transfer printing, embossed plates, mechanical engraving, hot stamping, 3D printing, water transfer, UV digital printing.

- Texture: In-mold texture(IMD, IML, IMG) or post-processing(sandblasting, coating, nameplating, decals, machining, etc.).

- Packaging: Transport packaging includes heavy-duty corrugated boxes, protective pads (plastic bags, foam guards, honeycomb cardboard), strapping tapes, and wooden pallets; Gift packaging – printed sleeves, offset printing gift boxes, fabric storage bags, etc.