Wholesale Custom Cooler Boxes Manufacturer

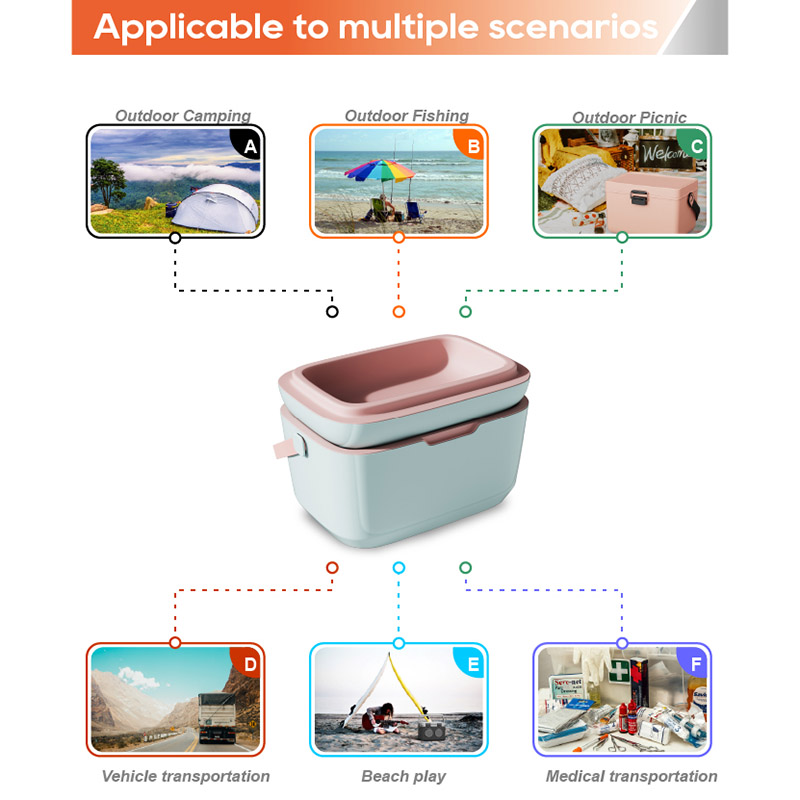

As an experienced hard cooler manufacturer, we possess multiple production lines and comprehensive manufacturing capabilities to support your requirements. Our existing ice chest models are suitable for various application scenarios, from harsh outdoor survival situations to relaxed picnic and camping activities. We offer coolers that balance budget and performance. We focus on high-end rotational molded hard coolers, light-weight and low-cost blow molded ice chests, and multi-purpose injection molded ice cooler boxes to ensure a perfect balance between insulation efficiency, portability, and manufacturing costs. We provide fully customized services, including colors, sizes, private logos, and patterns, enabling us to transform your ideas and sketches into market-leading products.

KingStar Wholesale Hard-Sided Coolers

GET CUSTOM QUOTE NOW

TIERED PRICING FOR BULK ORDERS!

Your Brand, Backed by Proven Excellence

Global Compliant & Quality Assured Cooler Boxes & Ice Chests

We are well aware that compliance is crucial for your entry into the market. Our factory has passed the BSCI audit, and all products are made from environmentally friendly materials that comply with FDA and LFGB standards. Whether your target market is North America, which values ultimate performance, or Europe, which emphasizes environmental safety, we can provide you with a complete compliance package, helping your brand smoothly pass through customs and win the trust of consumers.

| Certification | Focus Area | Description |

|---|---|---|

| FDA / LFGB | Food-Grade Safety | Ensure that all lining materials are non-toxic and suitable for direct contact with food, which is of crucial importance for market access in Europe and the United States. |

| IGBC | Bear-Resistant | It can verify the structural integrity of the product under extreme physical forces in the wild, targeting the high-end outdoor market in North America. |

| RoHS / REACH | Chemical Compliance | Guarantees the product is free from hazardous substances and eco-friendly. |

| ISO 9001 | Quality Management | Demonstrates factory reliability and manufacturing maturity. |

| BSCI / SEDEX | Social Responsibility | Moral production audits covering labor rights and working conditions. A mandatory entry requirement for major retailers like Walmart, Target, and Costco. |

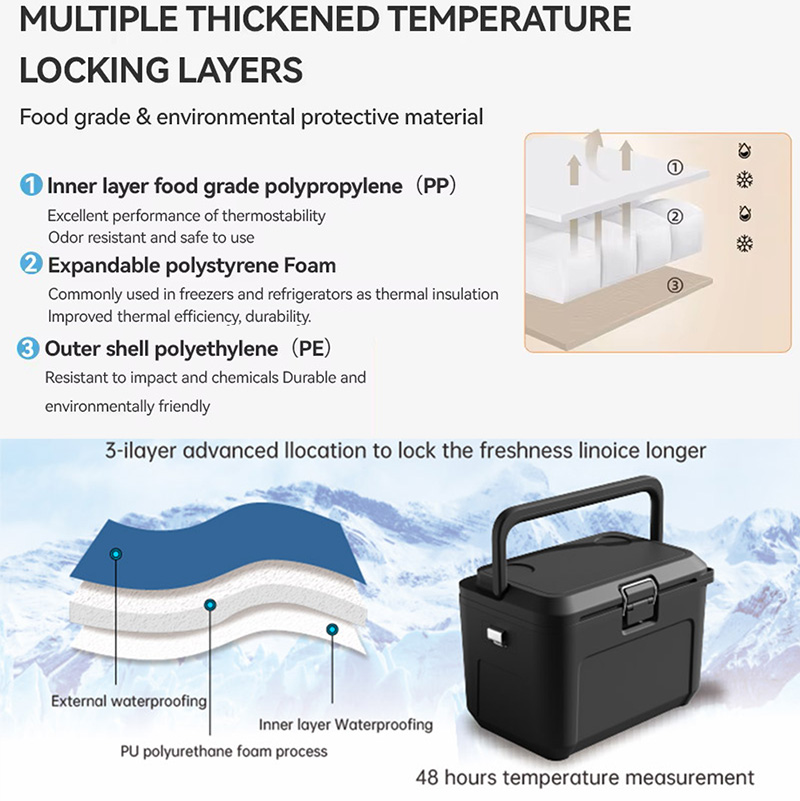

High-Quality Hard Cooler Molding Techniques

Hard Cooler Customization Options

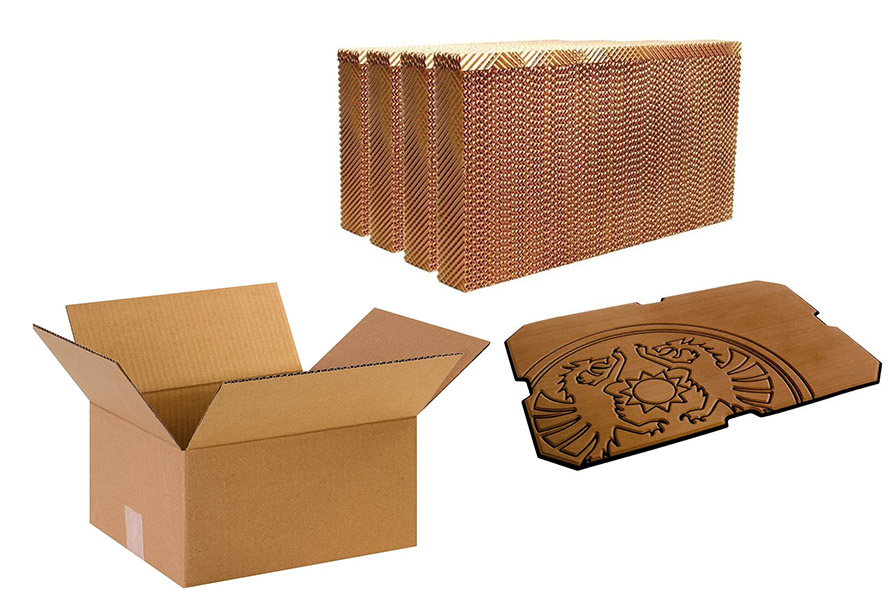

Manufacturing Capabilities & Packaging Solutions

- Rotomolding: For extreme ice retention (5-7 days) & heavy-duty use.

- Blow Molding: For the perfect balance of weight and 2-4 day cooling.

- Injection Molding: For precision design, stylish aesthetics, and portability.

Transport packaging includes heavy-duty corrugated boxes, protective pads (plastic bags, foam guards, honeycomb cardboard), strapping tapes, and wooden pallets; Gift packaging – printed sleeves, offset printing gift boxes, fabric storage bags, etc.

Your Custom-Designed Plastic Hard-Sided Ice Chest Manufacturer Factory

Custom Hard Cooler Mold Tooling Process

Step 1: Sign NDA

NDA is the abbreviation of Non-Disclosure Agreement. Before you disclose any confidential information (such as drawing or design concepts) about your custom water bottle project, we sign NDA with you.

Step 2: Complete Design Drawing

Base your drawing, our engineering team will release DFM (Design For Manufacturing) report and help revise the drawing. If you only have a design concept without drawings, our R&D team offers design support to complete the drawing.

Step 3: Quotation & Payment

After having all your requirement, we quote for both tooling cost and product pricing. Payment term for tooling is that, 50% deposit and 50% after sample approved by you. Payment term for mass production is normally 30% deposit + 70% balance before shipment.

Step 4: Tooling Fabrication & Sample Approval

Lead time of tooling fabrication is 5 weeks. You will get a 3D printed prototype sample to finalize the design, and T1, T2 samples for final approval on your custom mold design bottle tumblers.

Step 5: Mass Production

After T2 tooling sample is approved and deposit payment received, we then start mass production. The lead time of mass production is 45 days. It’ll be even longer for custom design smart water bottle projects.

Step 6: Final Payment & Shipping

After receiving final payment, we will work with your forwarder to arrange the shipment. If you have no experience in importing from China, we can handle the whole logistics and arrange globally door-to-door shipping.

FAQs About Wholesale Plastic Insulated Hard Cooler Boxes

We’ve compiled a list of the most frequently asked questions to make it easier for you to find the information you need. Whether you’re looking for details about our wholesale blank bottles or custom beverage containers, you can quickly access helpful answers here.

Knowledge Of Bulk Ice Coolers & Ice Chests