Imagine pouring steaming coffee in the morning, only to find it still piping hot in the evening, or dropping a few ice cubes into your bottle at sunrise and discovering them intact at sundown. This everyday magic isn’t just luck or chance, it’s the result of a sophisticated design hidden behind the stainless steel. At the heart of this design lies the vacuum layer, an unsung hero that dictates whether your bottle is merely good or truly exceptional. Understanding its role reveals why some bottles outperform the rest, shaping not just user satisfaction but a product’s reputation for quality.

Anyone who has ever taken a sip of coffee that is still hot in the evening, or fished out a whole ice cube from a bottle at the end of the day, has experienced the quiet victory with good insulation. It appears to be a simple stainless steel bottle, but in fact, it is a complex thermal system. The core of this system is the vacuum layer, an inconspicuous element that few people notice, but it is so decisive that it determines whether a thermos bottle is merely adequate or exceptionally good. For brands and buyers, this distinction is not theoretical; This is the difference between a showroom-ready design and a product that earns real trust in daily use.

What Is the Vacuum Layer, And How Does It Reduce Heat Transfer?

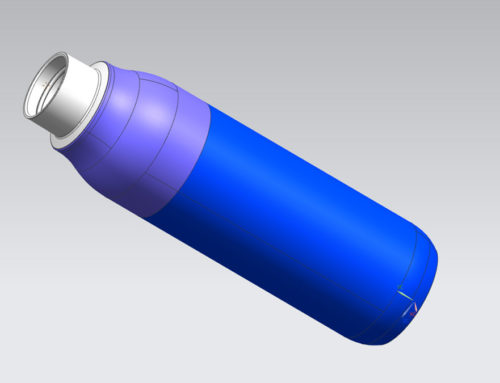

The principle of vacuum insulation is simple and ingenious. The vacuum flask / thermos cup / tumbler / beer growler / food container / shaker bottle uses a structure made of two stainless steel walls, with a narrow, sealed gap between them. During manufacturing, air is pumped out of this gap until almost no air or gases remain, creating a vacuum layer, aka vacuum insulation technology. This vacuum layer (meaning a space without air or other gases) serves as a barrier that greatly slows down heat transfer between the liquid in the cup and the outside environment.

The reason why a vacuum has such an excellent heat insulation effect comes from the basic physical principle of heat transfer. In a normal space filled with air, heat transfer is very smooth because air molecules will bring energy from a high-temperature region to a low-temperature region. Once these molecules are removed, the normal transmission path of heat is lost. The role of heat conduction will be minimized, because there is no medium between the cup walls that can effectively conduct energy; Thermal convection will be basically eliminated, because the occurrence of convection depends on air flow, and there is no condition for air flow in a vacuum environment; As for the remaining heat transfer path-thermal radiation, it can be further weakened by the reflection treatment of the inner wall. This reflection treatment is usually supplemented by a copper plating process, and its function is to reflect heat energy back to the source, rather than letting it dissipate. The ultimate realisation is not a small improvement in performance, but a fundamentally different heat retention mechanism.

Why Does Vacuum Insulation Outperform Foam And Air-Gap Designs?

Compared with the thermal insulation method that still relies on air or filling materials, the well-formed vacuum layer can realise a leap-forward improvement in performance. Although foam can slow down heat transfer, it can’t eliminate heat convection and heat conduction like a vacuum layer, and the heat retention performance is easy to decay with time. At the same time, air still exists in the air sandwich design, that is to say, there is a medium to promote heat transfer in this structure.

By comparing and testing different design schemes under controlled test conditions, the advantages of the vacuum layer will be obvious.

| Double-wall vacuum | ~0.5–1°C | 12–24+ hours |

| Foam insulation | ~2–3°C | 6–8 hours |

| Air gap only | ~4°C or more | 2–4 hours |

Why Is Vacuum Pumping Important During Insulated Water Bottle Production?

“Vacuum insulation” is not empty talk, but a real manufacturing process. In order to form a stable vacuum layer, it is necessary to go through a vacuum pumping process: this is a set of controlled processes, in which the air and impurities between the interlayer of the inner and outer cup walls are pumped away first, and then the interlayer is sealed to ensure that the product can maintain a vacuum state throughout its service life. Once the vacuum is not completely evacuated or the integrity of the seal is broken, no matter how high-end the cup looks on the outside, its thermal insulation performance will decay, sometimes at a rapid rate.

High-quality production links will regard vacuum pumping as a precise operation, not a routine procedure. In the production process, it is necessary not only to continuously and stably reach the target vacuum degree, but also to keep the pressure holding time long enough to eliminate residual gas, and then complete the sealing through the process without micro-leakage. In actual production, welding precision and welding quality are very important. The characteristics of the vacuum layer have always been harsh: it doesn’t care how beautiful the powder coating on the cup is, and it won’t be moved by the brand story of passive people. Once the gas gradually penetrates into the interlayer, the thermal insulation performance of the product will decrease, and the cups and pots will quietly “age” and become mediocre.

Vacuuming Machine for Insulated Water Bottle Manufacturing

Which Other Factors Influence Insulation Performance Besides The Vacuum Layer?

Although the vacuum layer is the core factor to determine the heat insulation performance, it does not work alone.

The selection of materials is very important. The properties of different types of stainless steel are different in practical use, corrosion resistance and long-term cold and hot cycles. Most products are made of 304 stainless steel, which is enough to meet the daily needs. High-end products usually use 316 stainless steel to achieve better corrosion resistance and durability in harsher environments. The heat insulation performance will also be affected by the heat insulation treatment process of the inner wall. The purpose of the heat insulation treatment process of the inner wall is to reduce the heat radiation transmission, and the application of the copper plating process is often to strengthen the functions, not the simple decorative effects.

The selection of the design scheme will also affect the long-term stability of heat insulation performance. The thickness of the cup wall needs to be balanced between durability and weight, not the thicker the better. If the design optimisation is not in place, it will only increase the weight of the product and will not improve the thermal insulation performance. The sealing system of the lid is another common weak link. If the interface design is not reasonable, the cup cover will become a heat dissipation channel. For this reason, the mould development, sealing structure design and production consistency of the lid are by no means “subsidiary links” of the insulation system, but an indispensable part of the whole system.

Conclusion

In the final analysis, the vacuum layer is the invisible key factor that determines the success or failure of vacuum flask design. You can’t directly see it in actual use, but the requirements for the production process are unambiguous. When the process is up to standard, it can give the product excellent heat insulation performance and durability, and bring users a worry-free and convenient experience; When the process is not up to standard, no matter how sophisticated the appearance is, no matter how clever the product name is, no matter how gorgeous the marketing copy is, it can’t make up for this defect.

Whether you are evaluating thermos products for retail selection, promotion, customisation or a large-scale enterprise procurement plan, you should start with the vacuum layer and the rigorous manufacturing process behind it. Because consumers are never won over by specifications on paper, but by a product that continues to perform long after the novelty wears off. Make your everlasting cooperation with an experienced insulated water bottle manufacturer today. Contact KingStar at: sales@waterbottle.techor leave online message.