Owala bottles are stylish and functional, and they’ve held their own in fierce showdowns against established rival brands, such as Stanley. With a growing fan base and outstanding products, Owala has captured the attention of both hydration enthusiasts and fashion-forward consumers. However, as consumers and curious entrepreneurs, we couldn’t help but point out the elephant in the room: What are customers paying for when they swipe their card and bring home one of these iconic bottles? As demand for product transparency and sustainable practices continues to rise, consumers are more eager than ever to understand the true value beneath that trendy exterior.

KingStar, a leading wholesale water bottle manufacturer, is here to break down the cost to manufacture Owala Water Bottles for those who are interested. Keep reading to discover the secrets behind what really goes into Owala’s pricing, and understand why manufacturing costs feel surprisingly low in light of their premium retail tags.

The Overall Cost of Owala Water Bottles

What Consumers Actually Pay For

To estimate the overall cost of manufacturing Owala Water Bottles, it is best to break down the retail price from the customer’s perspective first. It is universally acknowledged that manufacturing costs are almost never equal to the retail price or selling price. Consumers are not just paying for the physical product itself. They are also covering costs like brand markup, the retailer’s profit margin, marketing campaigns (including influencer deals), and post-purchase services such as warranty and customer support, which are all factored into the final price. As a result, the typical Owala Water Bottle comes down to anywhere between $27.99 $41.99. You can usually find them at large chain stores like Walmart, Amazon, and Target, and browse through special edition bottles as well.

In other words, the upfront manufacturing cost is just one piece of the value chain: the rest of the price tag reflects marketing, logistics, design, guarantees, and profit layers.

Why This Matters: Transparency and Consumer Awareness

In today’s market, ethical production and supply chain transparency aren’t just buzzwords. They’re consumer priorities. Knowing how much of your purchase supports fair labor practices and environmentally responsible manufacturing empowers you to make informed choices. By understanding the full breakdown of costs, you gain insight into how your money supports quality control, safe materials like BPA-free plastics and stainless steel, and the brand’s bigger sustainability goals.

According to their official website, Owala bottles are built with long-term sustainability in mind, using materials like BPA-free plastic and stainless steel to create a durable, reusable alternative to disposable plastic. However, certain models blend materials, such as combining metal with plastic, which can complicate the recycling process despite their eco-conscious design.

For consumers and business owners looking to source such products, we are obliged to dig deeper into these issues and support brands that share sourcing details and sustainability credentials. Only in this way are we better equipped to back companies whose values align with our own.

A Detailed Breakdown of Owala Water Bottle Manufacturing Costs

Now that we’ve covered the retail price of Owala Water Bottles, it’s time to officially dive into the manufacturing costs for businesses that source such products.

When estimating the total manufacturing cost of Owala bottles, structured sourcing data for standard stainless steel insulated bottles indicates a typical FOB price of around US$3–5 per unit for large orders (e.g., 10,000+ units), before customization or shipping.

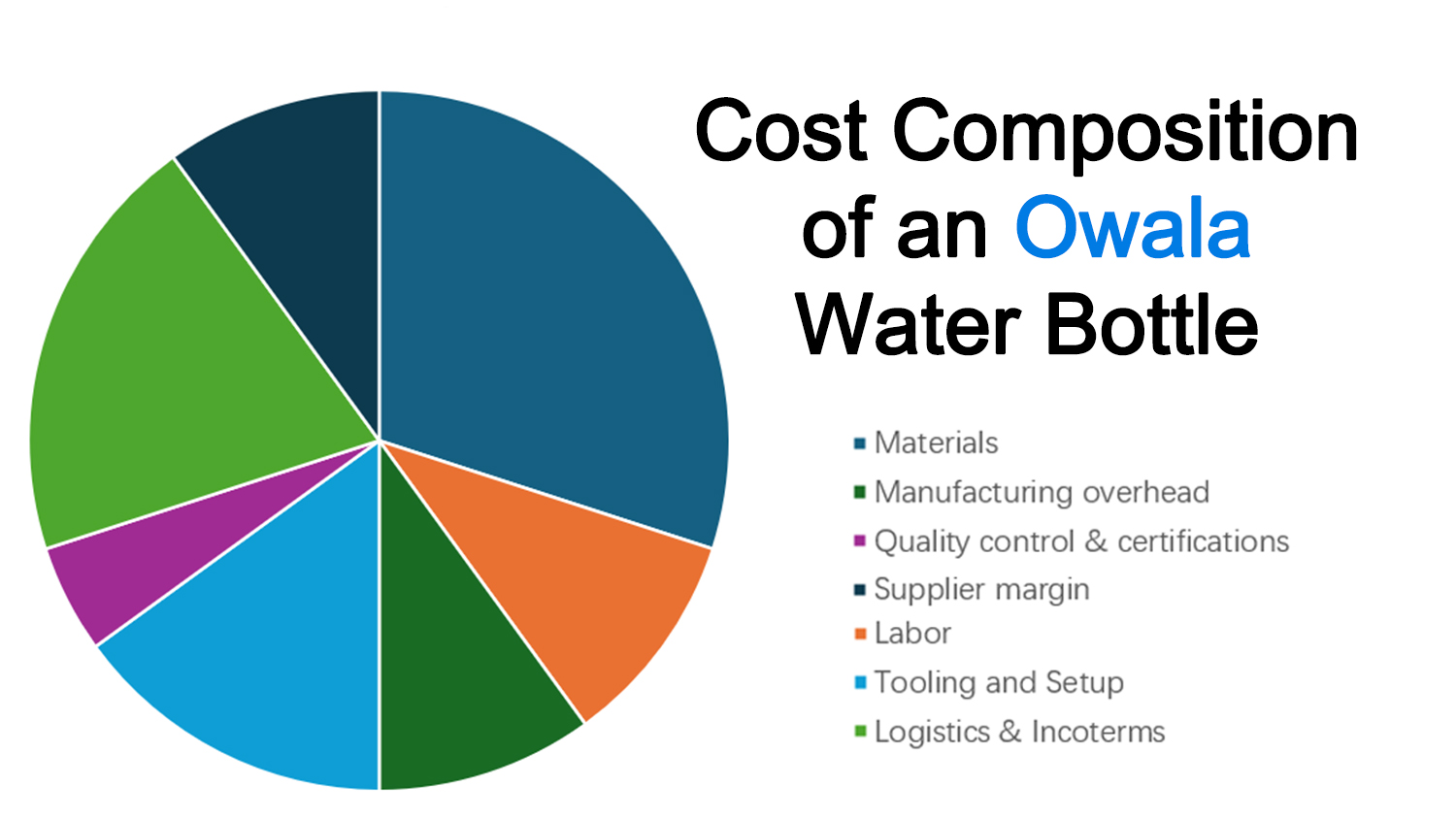

These estimates include:

- Materials (mostly 18/8 stainless steel, BPA-free plastic, silicone seals): around 30–50% of unit cost.

- Labor in China or similar low-cost regions: typically 10–15%.

- Manufacturing overhead (machinery depreciation, utilities, QC): adds 10–15%, with more efficiency at scale.

- Tooling and setup for molds and customization: amortized across large production runs, but significant upfront (often several thousand USD). Smaller runs drastically increase per-unit costs.

- Quality control & certifications (FDA, ISO, CE): typically add 5–8% to costs.

- Logistics & Incoterms (shipping, customs, duties): can account for 10–25% of landed cost depending on destination and shipping terms.

- Supplier margin: manufacturers usually aim for a 10–30% profit margin.

Smaller order sizes and extensive customization (e.g., special finishes, custom logos, unique lids) can raise the unit cost substantially.

A Typical Owala Water Bottle’s Cost Composition

Manufacturing Location and Its Impact on Cost

Where you choose to make your water bottles dramatically influences your bottom line. Although Owala is an American brand, the actual production of its water bottles takes place overseas, most commonly in countries like China, where large-scale manufacturing of consumer goods is well established.

According to sources like Asia Agent, Chinese factories remain the go‑to for high‑volume, cost‑efficient production. Average manufacturing wages there amount to just 20 percent of U.S. labor rates, even after recent wage growth, making it a powerful draw for brands like Owala.

Meanwhile, Southeast Asian hubs (Vietnam, Malaysia, Thailand) often undercut China on direct labor costs, though lower productivity and longer lead times can offset those savings, especially for complex, precision‑engineered lids or custom finishes.

By contrast, stateside manufacturing delivers unparalleled control and shorter supply chains but at a labor cost that can be four to five times higher than China’s. Add in stringent environmental regulations and higher energy prices, and U.S. production can push per-unit costs well above the $5 mark, which sometimes doubles Chinese FOB rates.

Tariffs, Certifications, and Hidden Fees

On top of base labor and materials, import duties and compliance expenses can tug heavily at margins. Stainless‑steel drinkware imported into the U.S. typically carries a 2.9 percent ad valorem duty under its HTSUS classification, plus a blanket 10 percent tariff on all Chinese goods and an additional 25 percent Section 301 surcharge on steel components. Some products even incur a 20 percent “fentanyl mitigation” tariff, taking total duties into the 57–60 percent range.

Why Ordering From Chinese Manufacturers Like KingStar Pays Off

Wholesale arrangements made with Chinese manufacturers like us offer immense benefits, one of which is their expertise in manufacturing premium-quality insulated water bottles. Take KingStar as an example. It is a recognized leader in the drinkware and vacuum-insulated container industry, proudly partnering with top-tier OEM and ODM clients including Yeti, Hydro Flask, Starbucks, Thermos, Stanley, Walmart, and others. To top it all off, beyond working with top-performing brands, it has also supported countless startups in bringing their eCommerce drinkware ideas to life.

For small businesses with ambitious goals, working with an experienced Chinese manufacturer like KingStar can be a game-changer. From flexible minimum order quantities to full-service support, including product development, custom branding, packaging, and logistics, KingStar provides the tools and infrastructure needed to scale efficiently. Their in-house engineering and quality control teams ensure each bottle meets international standards, while their familiarity with Amazon FBA requirements streamlines the fulfillment process for online sellers.

Notably, our production capabilities enable us to craft water bottles that align with the quality, material specifications, functional design, and structural precision of leading market options—with the added advantage of full customization support. Whether you need to tailor colors, add unique logos, adjust sizing, or incorporate brand-specific details, we can deliver products that match the performance and craftsmanship of top models while carrying your distinct brand identity with customizable packaging.

Wholesale FreeSip Water Bottles Vacuum Insulated Stainless Steel Unit price: USD2.69

40 oz Stainless Steel Tumbler Silicone Sip Metal Straw Unique Design Patented Unit price: USD 3.98

In conclusion, the Owala Water Bottle costs more than generic versions of drinking utensils, but its quality, innovation, and design justify the extra cost. Next time you sip from your Owala, you’ll know what went into it!

If you’re someone who’s looking to build a brand that can rival esteemed brands like Owala and wants to source premium products without spending an excessive amount of money, KingStar is your ideal wholesale partner. Just send an email to sales@waterbottle.tech or leave an online message on our website on contact page, and we’ll help you get started on your promising business venture! We promise that you won’t be disappointed.