Here’s the direct answer to your core question: When customizing corporate water bottles, selecting high-quality 304 or 316 stainless steel, combined with professional surface treatments like passivation, results in nickel release levels that fully comply with international food safety standards. This makes them perfectly safe for over 99% of use cases. The so-called “nickel-free” claim is often unnecessary; the real keys are the material grade and the manufacturer’s process control.

As a manufacturer that has long collaborated with various brands, we often encounter such consultation scenarios: The purchasing manager of the enterprise holds a beautifully designed water bottle prototype, but gets stuck at the last moment by the issue of “material safety” – “We want to use stainless steel, but we heard that some people may be allergic to nickel?” ” Some products in the market advertise as ‘nickel-free,’ should we choose that instead?”

We fully understand this concern. When a gift that represents the company’s intentions might raise concerns due to an extremely low probability of material risks, the pressure to make a purchasing decision is immense. But the truth is that much of the anxiety stems from information asymmetry and misleading marketing in the market.

Based on our years of production and quality control experience, we will help you clarify the truth about stainless steel water bottles and “nickel safety”, and assist you in making a professional and reliable purchasing decision.

Why Should “Nickel” Be a Consideration When Customizing Water Bottles?

Today, customized water bottles / tumblers / can coolers / jugs / shakers have transcended their role as simple gifts. They are carriers of corporate care, brand philosophy, and sustainability commitments. When you choose a daily-use item for employees or clients, safety is the baseline and the starting point of the experience.

We engage with many clients, especially from healthcare, high-end services, or industries that prioritize employee well-being, who explicitly ask: “Could your water bottles cause metal allergies?” This concern is not unfounded. The market is flooded with low-cost products made from non-food-grade stainless steel (like types 201, 430, or recycled materials). Their metal stability is poor, and elements like nickel are more prone to leaching, posing a genuine risk.

As a manufacturer, our responsibility extends beyond production to providing reliable “material solutions.” Choosing genuinely safe stainless steel (like 304/316) paired with rigorous processes is the way to solve the problem at its source.

Why Does Stainless Steel Cause Allergies For Some People?

First of all, we need to understand that most people who claim to be allergic to “metal” or “stainless steel” are actually allergic to the “nickel” contained within them.

Nickel allergy is a common type of contact allergy, often occurring in items that come into prolonged, close contact with the skin, such as earrings and watch bands. The usage scenario of a water bottle varies, but if the material of the bottle body (especially the inner container) is unstable, when holding acidic beverages (such as lemonade, coffee), trace amounts of nickel ions may leach out. For extremely sensitive individuals, discomfort may occur around the lips or on the hands after drinking or touching.

The key words here are “trace amounts” and “extremely sensitive”. The cookware and tableware we commonly use, as long as they are made of the genuine 304/316 materials, the amount of nickel released is far below the international safety standards. Most people can use them with peace of mind. In simple terms, an allergy usually requires two conditions: one is that the material is prone to releasing nickel, and the other is prolonged skin contact. A high-quality stainless steel water bottle is unlikely to cause any problems.

Why Do Most Stainless Steels Contain Nickel?

Many customers may ask: “Since it could cause allergies, why not just completely remove nickel?” This touches upon the core of materials science.

Nickel is one of the most important components in stainless steel:

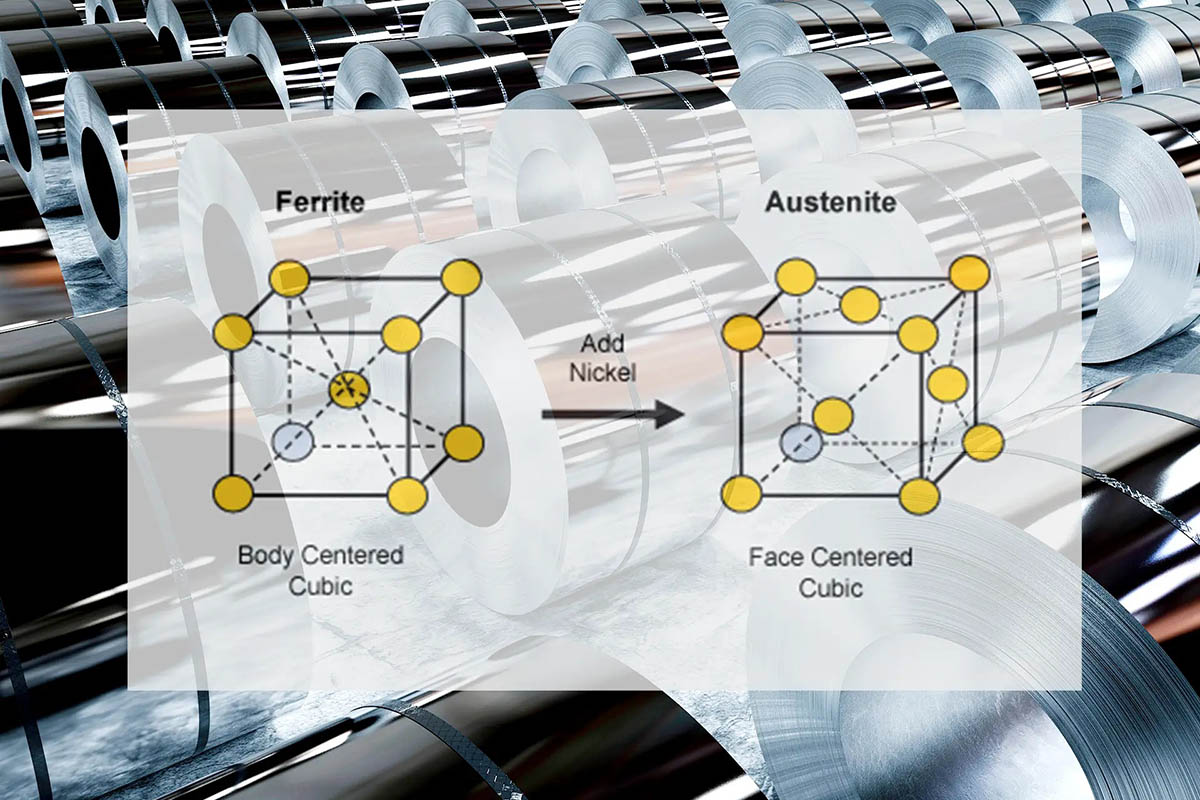

- It makes stainless steel more resilient and resistant to corrosion (forming a stable “austenitic structure”), enabling it to withstand processing, welding, and daily impacts. And corrosion resistance is precisely one of the most essential characteristics for the inner lining material of the insulated bottle, because users may use it to store various liquids other than pure water, such as juices, carbonated beverages, milk, and so on for a long period of time.

- It makes the surface easier to polish to a mirror-like smoothness, less prone to dirt accumulation, and easier to clean.

Stainless steel without nickel (such as 430) would have significantly reduced corrosion resistance and forming processing performance, be prone to rusting, and not suitable for manufacturing high-quality thermos that need to come into prolonged contact with various liquids and are subject to complex processes. Therefore, choosing 304/316 stainless steel, which contains nickel, is precisely to pursue higher safety and durability.

Why Choose SS304/SS316 for the Inner Liner of Insulated Water Bottles?

What determines safety is not the “total content” of nickel, but its “release amount”. This is similar to a container with excellent sealing performance. No matter how much water it contains, it will not leak out.

304 (with a nickel content of approximately 8%-10.5%) and the more premium 316 (with a nickel content of approximately 10%-14%) have extremely stable metal structures. The nickel is firmly “locked” in the alloy lattice. They fully comply with global mainstream food contact material standards such as China’s GB 4806.9, the US FDA, and the EU (EC) No 1935/2004. These standards strictly limit the migration limits of heavy metals like nickel, and the measured values of 304/316 are usually far below the limits.

An interesting comparison is: The nickel content of 316 stainless steel is slightly higher than that of 304. However, due to the addition of molybdenum, its corrosion resistance (especially against chloride, such as salt water) is stronger. In practical use, the release of metal ions may be lower, and it is more stable. This is why high-end water cup brands generally use 316 as the inner liner material.

How to Reduce the Impact of “Nickel” to the Lowest Extent?

Selecting the right materials is just the first step. In our factory, through core process control, we ensure that every water bottle produced achieves “ultra-low migration”:

- Passivation: This is the most crucial step. We precisely control the temperature, concentration, and duration of the passivation solution based on the material, forming a thicker, denser, and more uniform chromium oxide protective film on the surface of the steel body. This layer acts as an “isolation barrier”, effectively preventing the release of metal ions (including nickel).

- Inner wall electrolytic polishing: For inner containers with high-gloss mirror surface requirements, we use electrolytic polishing. It not only removes microscopic burrs and makes the inner wall smooth like glass, but also further optimizes the surface passivation layer, enhancing the anti-corrosion and water-proofing capabilities.

- Special treatment of welding areas: The welding area at the bottle bottom is potential weak point. We use precision welding techniques such as argon arc welding, and then perform meticulous internal polishing and local secondary passivation after welding to ensure that this area has the same corrosion resistance as the bottle body.

- Control from source material: We only purchase refined steel coils from factories with complete material certificates (MTC), and never use unidentified “non-standard materials” or low-cost 201 steel. Our quality inspection laboratory will regularly conduct salt spray tests on raw materials and finished products to simulate extreme environments and verify their corrosion resistance.

These process details are the dividing line of a manufacturer’s professionalism and also the “invisible value” that B2B customers should pay the most attention to.

“Nickel-Free”: When Is It Truly Necessary?

For the vast majority of enterprises and users, the 304/316 stainless steel bottles that have undergone standardized treatment are absolutely safe and the best choice.

Only when your target group consists of a specific population that has been clinically diagnosed with severe nickel allergy (such as certain hospital departments or allergy research institutions) should you consider truly “nickel-free” special alloys (such as certain titanium alloys or specific coating technologies). Please note that these materials are extremely costly, difficult to process, and may compromise other properties (such as heat retention and durability).

Our suggestion is: Do not sacrifice the comprehensive performance and cost-effectiveness of the product for a very low probability of risk. Ensure that the supplier uses genuine 304/316 food-grade stainless steel and has a complete passivation process. This is a more practical and reliable choice.

B2B Core Advantage: Why Pay Attention to “Nickel Safety” and Why It’s Crucial for Your Enterprise’s Procurement

- Mitigate Procurement Risk & Enhance Gift Acceptance: Eliminate potential complaints or health concerns caused by material issues from the source, allowing your care and kindness to be perfectly conveyed.

- Strengthen Your Brand’s Responsible Image: When you can clearly convey to your employees or customers that “we strictly control material safety for you”, this itself is a powerful demonstration of the brand’s values of “people-oriented” and “detail-focused”.

- Gain Authentic Marketing Messaging: You can confidently use expressions such as “food-grade safe inner liner”, “compliant with international food contact standards”, and “skin-friendly metal material”, adding highlights to your corporate social responsibility (CSR) report or sustainable marketing.

- Ensure Long-term Use and Protect Brand Reputation: A reliable, reusable water bottle with excellent material and solid craftsmanship has a long lifespan, is not prone to dirt or odors, and can accompany users for a longer time, continuously exposing your brand. Good products speak for themselves.

Why Choose KingStar As Your Custom Stainless Steel Water Bottle Manufacturer?

As the leading wholesale water bottle manufacturer, we believe that excellent custom products stem from respect for materials and dedication to craftsmanship.

- We offer one-stop, traceable custom services: From material certification, process selection to logo customization (laser engraving, powder coating, heat transfer, etc.), the entire process is transparent and controllable. We are particularly good at handling complex demands and consistency in quality control for large-scale corporate gift orders.

- We respond to your business inquiries as if answering technical questions: Our sales team is supported by engineers, and they are willing to discuss with you how to realize your brand concept through the most suitable materials and processes.

If you are looking for a truly reliable and brand-reflective custom water bottle for your enterprise, please feel free to contact us (sales@waterbottle.tech) at any time. You can bring your initial idea sketches or samples, or you can just select our customizable standard models and let us provide you with a reliable solution from a manufacturing professional perspective.