Contents

- 1 Introduction

- 2 The trend of industrial robot technology application

- 3 The application

- 3.1 The application of automated mechanical arm in the stretching process

- 3.2 The application of welding robots in the water bottle production line

- 3.3 The application of handling robot in thermos cup factories

- 3.4 The application of inspection robots in stainless steel drinkware

- 4 Factors should be considered for their application in the thermos cup industry

- 4.1 Technical basis

- 4.2 Economic benefits

- 4.3 Personnel factors

- 5 Concluding remarks

With the rapid development of robotics and automation technology, there has been an increasing application of them in insulated water bottle manufacturing industry. Industrial robots are a mechanical device that automatically performs manufacturing tasks and they can operate according to a pre-designed program. As a leading vacuum insulation water bottle manufacturer, KingStar is committed to promoting the application of industrial robots in the manufacturing of vacuum double-walled stainless steel containers/vessels, with the main purpose of improving the quality. To this end, this article discusses and analyzes the application of automatic production technology of stainless steel drinkware based on industrial robots, hoping that this article can shed a light on the design, research and development as well as manufacturing of the water bottle industry.

1. Introduction

As an advanced manufacturing technology, industrial robots have played a great role in the automation of manufacturing bulk stainless steel water bottles. Therefore, this paper will first introduce the development trend of the application of industrial robots both at home and abroad, further discussing the application of automatic production technology of stainless steel water bottles, and then the paper analyzes the factors that should be paid attention to in the application of automatic production technology of wholesale stainless steel water bottles based on industrial robots. Manufacturers of stainless steel bottles can therefore reduce labor costs and improve the quality of thermos container /vessel. Stainless steel bottle mug cup buyers can also reduce the purchase price.

2. The trend of industrial robot technology application

The number of industrial robots in the world is increasing. More and more robots are now being widely used and they enjoy a good market prospect. According to statistics, the number of industrial robots in the world has reached more than 35.3 million, of which Asia has the most prominent growth rate. Industrial robots are becoming more precise, intelligent and miniaturized. They are widely used in many fields such as agriculture, construction, medicine, military. Practice has proved that industrial robots play an important role in completing complex tasks, improving automation level and boosting economic benefits.

3 The application

3.1 The application of automated mechanical arm in the stretching process

The stretching is an important manufacturing process of metal tumbler cups, double wall stainless steel bowls for pets such as dogs and cats. The automatic stretching technology will make the inner side of water bottles smooth and stemless.

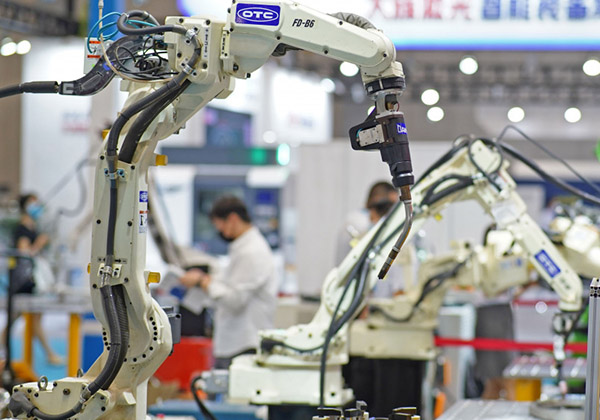

3.2 The application of welding robots in the water bottle production line

As the name implies, a welding robot is about wielding. Different welding robots are used for different welding types, generally including spot welding robots, arc welding robots and laser welding robots. Welding robots was introduced to the KingStar’s water bottle production line in 2015, and the arc welding and spot welding robots are the most frequently used ones.

3.3 The application of handling robot in thermos cup factories

The handling robots complete the given task through the end effector. The end effector varies because the shape and size of semi-finished thermos cups from different working procedures are different. The handling robots have a wide range of applications, which can be in the production processes of thermos cups such as loading and unloading in the water expanding process / stretching process moving the turnover box, automation of assembly line, automatic loading and unloading in vacuumizing process and so on. There is a wide range of application of the handling robots and no expertise is required which allows employees to take the job immediately and helps save a lot of manpower and material resources for water bottle maker, thus reducing the production cost.

3.4 The application of inspection robots in stainless steel drinkware

The inspection robot is a robot that can inspect the quality of stainless steel cups. It can verify the quality of the thermos cup through multiple sensors such as vision, light perception and touch. At present, the use of inspection robots is relatively rare.

4 Factors should be considered for their application in the thermos cup industry

The application of automated robots in the thermos cup manufacturing industry should be taken seriously. Before applying automated robots or robotic arms, there are three aspects that should be taken into considerations:

4.1 Technical basis

Robot is not an isolated part, so the application of stainless steel water bottle production line needs to pay attention to some supporting technical transformation problems such as the information connection with the original equipment, whether the replacement of robots can meet the requirements of the original process rhythm and product characteristics, will the original equipment space layout be restricted and need to be readjusted and whether the operation method should be changed or not, and so on.

4.2 Economic benefits

The main purpose of using robots is mainly to save labor and improve the quality of stainless steel water cups. The application of robots has to consider its financial return on investment (ROI). If the purchase cost of one robot and the technical transformation cost of supporting equipment are 800,000 yuan, and the replaceable labor contains 2 people. We regard the current labor cost of 80,000 per year.

Labor cost * number of people saved + 10% annual depreciation of equipment/robot cost = 80000 * 2+800000 * 10%/80000 = 30%

The annual return on investment is 30%, and in the fourth year, you can recover all the investment costs and realize the profit return. Robots can get high profit returns when they are automatically put into the production line of stainless steel cups.

4.3 Personnel factors

After the robots are put to work, the operation mode of employees will be changed completely. It is not just about simple repetitive work, and employees need to have higher robot operation skills. Such as robot teaching, position adjustment, troubleshooting, maintenance, etc. After the application of robots, manufacturers of stainless steel sports bottles must focus on training-related skilled workers.

5 Concluding remarks

In a word, with the continuous improvement of the intelligent level of automatic robots, industrial robots will be gradually applied in every process of manufacturing stainless steel water bottles / wholesale tumblers / custom mugs / cups / vacuum flasks / growlers / vessels / food containers / bowls / lunch boxes / food containers / OEM&ODM can coolers. Automation robots are developing in the direction of wider and deeper application in drink bottle factories. Robots can shorten handling and waiting time, improve product quality and efficiency, and reduce labor intensity. On the one hand, they can increase the market share of enterprises, on the other hand, they can greatly improve product quality as well as shortening the time span from research and development to mass production of new products.